Lecture 3 - Real shaft power cycles

advertisement

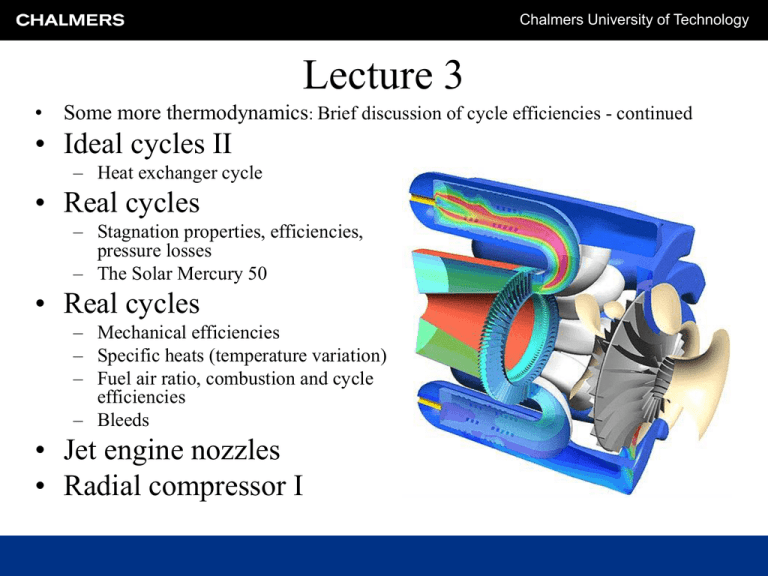

Chalmers University of Technology Lecture 3 • Some more thermodynamics: Brief discussion of cycle efficiencies - continued • Ideal cycles II – Heat exchanger cycle • Real cycles – Stagnation properties, efficiencies, pressure losses – The Solar Mercury 50 • Real cycles – Mechanical efficiencies – Specific heats (temperature variation) – Fuel air ratio, combustion and cycle efficiencies – Bleeds • Jet engine nozzles • Radial compressor I Chalmers University of Technology Generalization of the Carnot efficiency TL TL th,carnot 1 1 TH TH TL average cold temperature TH average hot temperature Is generalization of Carnot efficiency to Brayton cycle possible? Define average temp. to value that would give the same heat transfer, i.e.: 3 qin Tds T H s 2 1 qout Tds T L 4 s Chalmers University of Technology Generalization of Carnot efficiency But for the isobar we have, 0 T3 P3 T3 s c p ln R ln c p ln T2 P2 T2 Furthermore, we have Gibbs equation (Cengel and Boles): du Tds Pdv as well as: dq dw du d (h pv) dh pdv vdp Thus, the average temperature is obtained from (dp=0): T T TH s TH c p ln 3 Tds [combine relations ] c p dT c p T23 TH 23 T T2 2 2 ln 3 T2 3 3 Derive an expression for the lower average temperature in the same way. Chalmers University of Technology Generalization of Carnot efficiency th, Brayton T3 T4 T2 T1 T3 T2 T3 T4 T41 T2 T3 1 T32 T1 T4 T2 T1 T41 T4 ln TL TL T1 1 1 1 th,Carnot T32 TH TH T3 ln T2 Chalmers University of Technology Heat exchange cycle When T4 > T2 a heat exchanger can be introduced. This is true when: 1 r t 2( 1) Chalmers University of Technology Theory 3.1 – Ideal heat exchanger cycle Here we obtain the efficiency: c p (T3 T4 ) c p (T2 T1 ) c p (T3 T5 ) (T3 T4 ) (T2 T1 ) (T3 T4 ) Not independent of T3!!! (simple cycle is independent of t3) T2 1 1) (T2 T1 ) T2 T3 T1 T1 r T1 1 1 1 1 1 T2 T (T3 T4 ) T1 T4 T t 4 T4 ( 1) T3 1 T1 T2 T1 ( Power output is unaffected by heat exchangers since the turbine and compressor work are the same as in the simple cycle. Chalmers University of Technology Heat exchange cycle Very high efficiencies can be theoretically be obtained! Heat exchanger metallurgical limits will be relevant. T4 = 1000.0 K => 70% Chalmers University of Technology Heat exchange cycle What happens with the average temperature at which heat is added/rejected when the pressure ratio changes in heat exchange cycle? TH qin qout Low pressure ratio => high efficiency qin qout TH Chalmers University of Technology Cycles with losses a. Change in kinetic energy between inlet and outlet may not be negligible : Ve2 Vi 2 Q W m e he gze m i hi gzi 2 2 all exits e all inletsi b. Fluid friction => - burners - combustion chambers - exhaust ducts Chalmers University of Technology Cycles with losses c. Heat exchangers. Economic size => terminal temperature difference, i.e. T5 < T4. d. Friction losses in shaft, i.e. the transmission of turbine power to compressor. Auxiliary power requirement such as oil and fuel pumps. e. γ and cp vary with temperature and gas composition. Chalmers University of Technology Cycles with losses f. g. Efficiency is defined by SFC (specific fuel consumption = fuel consumption per unit net work output). Cycle efficiency obtained using fuel heating value. Cooling of blade roots and turbine disks often require approximately the same mass flow of gas as fuel flow => air flow is approximated as constant for preliminary calculations. This is done in this course. Chalmers University of Technology Stagnation properties • For high-speed flows, the potential energy of the fluid can still be neglected but the kinetic energy can not! Ve2 Vi 2 Q W m e he gze m i hi gzi 2 2 all exits e all inletsi V22 V12 [single input - single output ] m 2 h2 gz2 m 1 h1 gz1 2 2 0 0 h h 02 01 • It is convenient to combine the static temperature and the kinetic energy into a single term called the stagnation (or total) enthalpy, h0=h+V2/2, i.e. the energy obtained when a gas is brought to rest without heat or work transfer Chalmers University of Technology Stagnation properties V22 V12 q w h2 h1 h02 h01 2 2 h02 h01 For a perfect gas we get the stagnation temperature T0, according to: 2 V c pT0 c pT 2 2 V T0 T 2c p Chalmers University of Technology Stagnation pressure • Defined in same manner as stagnation temperature (no heat or work transfer) with added restriction – retardation is thought to occur reversibly • Thus we define the stagnation pressure p0 by: • Note that for an isentropic process between 02 and 01 we get P02 P02 P2 P1 P01 P2 P1 P01 T02 T2 1 T2 T1 1 T1 T01 P0 T0 1 P T 1 T02 T2 T1 T2 T1 T01 1 T02 T01 1 Chalmers University of Technology Compressor and turbine efficiencies Isentropic efficiency (compressors and turbines are approximately adiabatic => if expansion is reversible it is isentropic). The isentropic efficiency is for the compressor is: h c T c h0 c p T0 ' 0 Where ' p c , cp ' p ' 0 are the averaged specific heats of the temperature intervals 01-02´ and 01-02 respectively. Chalmers University of Technology Compressor and turbine efficiencies • Ideal and mean temperature differences are not very different. Thus it is a good approximation to assume: c cp ' p • We therefore define: T02 T01 c T02 T01 • Similarly for the turbine: T03 T04 t T03 T04 Chalmers University of Technology Compressor and turbine efficiencies T02 P02 T01 P01 1 T03 P03 and T04 P04 Using frequently used expressions: 1 T01 P02 1 T02 T01 c P01 T03 T04 1 T03 t 1 P03 P 04 1 1 produces the (2.11) (2.12) Chalmers University of Technology Turbine efficiency options • If the turbine exhausts directly to atmosphere the kinetic energy is lost and a more proper definition of efficiency would be: 1 1 T03 T04 T03t 1 P 03 Pa • In practice some of the kinetic energy is recovered in an exhaust diffuser => turbine pressure ratio increases. • Here we put p04=pa for gas turbines exhausting into atmosphere and think of ηt as taking both turbine and exhaust duct losses into account Chalmers University of Technology Turbine diffusers Recovered energy Chalmers University of Technology Heat-exchanger efficiency Conservation of energy (neglecting energy transfer to surrounding): c p , 46 T04 T06 c p , 25 T05 T02 In a real heat-exchanger T05 will no longer equal T04 (T05 <T04). We introduce heat exchanger effectiveness as: • Modern heat exchangers are designed to for effectiveness values above 90%. Use of stainless steel requires T04 around 900 K (or less). More advanced steal alloys can be used up to 1025 K. T05 T02 Effectiveness T04 T02 Chalmers University of Technology Pressure losses – burners & heat-exchangers • Burner pressure losses – Flame stabilizing & mixing pb pha P P02 1 – Fundamental loss (Chapter 7 + Rayleigh- 03 p02 P02 line appendix A.4) • Heat exchanger pressure loss – Air passage pressure loss ΔPha – Gas passage pressure loss ΔPhg – Losses depend on heat exchanger effectiveness. A 4% pressure loss is a reasonable starting point for design. pb 2 3% (industria l gas turbine) p02 pb 3 6% (aircraft engine) p02 Chalmers University of Technology The Solar Mercury 50 • 4.3 MW output • η = 40.5 % • System was designed from scratch to allow high performance integration of heat-exchanger Chalmers University of Technology Mechanical losses Turbine power is transmitted directly from the turbine without intermediate gearing => (only bearing and windage losses). We define the transmission efficiency ηm: Wturbine 1 m c p ,12 T02 T01 Usually power to drive fuel and oil pumps are transmitted from the shaft. We will assume ηm=0.99 for calculations. Chalmers University of Technology Temperature variation of specific heat We have already established: cp=f1(T) cv=f2(T) Since γ =cp/cv we have γ=f3(T) The combustion product thermodynamic properties will depend on T and f (fuel air ratio) Chalmers University of Technology Pressure dependency? At 1500 K dissociation begins to have an impact on cp and γ. K PH 2O P PO2 P 1 2 PH 2 P Detailed gas tables for afterburners may include pressure effects. We exclude them in this course. 1 H 2 O2 H 2O 2 1 CO O2 CO2 2 Chalmers University of Technology Temperature variation of specific heat In this course we use: c pa 1005 J/kg , a 1.400 c pg 1148 J/kg , g 1.333 Since gamma and cp vary in opposing senses some of the error introduced by this approximation is cancelled. Chalmers University of Technology Determining the fuel air ratio Calculate f that gives T03 for given T02? Use first law for control volumes (q=w=0) and that enthalpy is a point function (any path will produce the same result) 1 f c pg T03 298 f H 25 c pa T02 298 fcpf T f 298 0 f is small (typically around 0.02) and cpf is also small => last term is negligible. The equation determines f. Chalmers University of Technology Combustion temperature rise Hypothetic fuel: 86.08% carbon 13.92% hydrogen ΔH25 = - 43100 kj/kg Curves ok for kerosene burned in dry air. Not ok in afterburner (fin≠0). Chalmers University of Technology Shaft cycle performance parameters f SFC specific fuel consumption wN wnet cycle efficiency fQnet , p Chalmers University of Technology Bleeds • Combustor and turbine regions require most of the cooling air. • Anti-ice • Rule of thumb: take air as early as possible (less work put in) • Accessory unit cooling (oil system, aircraft power supply (generator), fuel pumps) • Air entering before rotor contributes to work! Chalmers University of Technology Aircraft propulsion – thrust generation Rate of change of momentum Net Thrust mC j mCa gross momentum thrust intake momentum drag Chalmers University of Technology Jet engine – principles of thrust generation Net Thrust m C j Ca A j p j pa Aircraft pressure thrust velocity Chalmers University of Technology Jet engine – principles of thrust generation No heat or work transfer in the jet engine nozzle V52 V42 q w h4 h05 h04 0 h5 2 2 0 0 h0 c pT0 h05 Stagnation temperature is constant T05 T04 h04 Chalmers University of Technology Mach number relations for stagnation properties 2 V We have already introduced the T0 T stagnation temperature as: 2c p and shown that (revision task): c p cv R The specific heat ratio γ is defined: cp cv The Mach number is defined as: V V V M * a speed of sound RT Chalmers University of Technology Mach number relations for stagnation properties Thus: M 2 RT c p 1 M 2 T T0 T T 2c p 2 R 1 T0 1 1 2 T M T 1 M 2 2 T 2 P0 T0 1 but we defined: which directly gives: P T P0 1 2 1 1 M P 2 Chalmers University of Technology Nozzle efficiencies Nozzle may operate choked or unchoked: T04 T5 j T4 T5 C52 Temperature equivalent 2c p Chalmers University of Technology Nozzle efficiencies Critical pressure for irreversible nozzle is obtained from: T04 T05 1 2 1 1 M T5 T5 2 2 T04 Tc j T04 Tc which gives: P04 Pc P04 T04 1 Pc Tc 1 1 1 j 1 1 1 Chalmers University of Technology Basic operation of radial compressor • Impeller - work is transferred to accelerate flow and increase pressure • Diffuser recover high speed generated in impeller as pressure Chalmers University of Technology Radial compressor operation • Typical design takes 50 % of increase in static pressure in diffuser • Conservation of angular momentum governs performance: Theoretical torque Rate of change of angular momentum Cw 2 r2 Cw1r1 prewhirl term Theoretical work Cw 2 r2 Cw1r1 for cases without prewhirl Cw 2 r2 Cw 2U 2 Chalmers University of Technology Slip factor Due to inertia of flow Cw2 < U: Theoretical work U 22 Stanitz formula for estimating σ 0.63 n n number of impeller vanes 1 Chalmers University of Technology Power input factor - • Power is put into overcoming additional friction not related to the flow in the impeller channels • Converts energy to heat => additional loss => Work done U 2 Chalmers University of Technology Overall pressure rise: p03 cU 1 p01 c pT01 2 1 • P03 is here used to denote the pressure at compressor exit. P02 is reserved for the stagnation pressure between the impeller and the diffuser vanes Chalmers University of Technology Example 4.1a • • • • • • • • ψ =1.04, σ = 0.90 N = 290.0 rev/s, D = 0.5 m Deye,tip = 0.3, Deye,root = 0.15 m = 9.0 kg/s T01 = 295 K P01 = 1.1 bar ηc = 0.78 • Compute pressure ratio and power required Chalmers University of Technology Learning goals • Understand why the Carnot cycle can be used for qualitative arguments also for the Joule/Brayton cycle • Be able to state reasonable loss levels for gas turbine components (turbine and compressor performance are given in Lecture 4) and include them in cycle analysis • Know how to compute cycle efficiencies for the heat exchanger cycle