Slide 1

advertisement

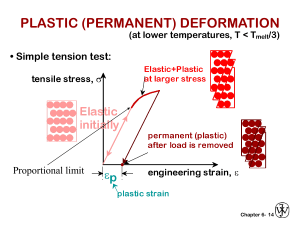

Poisson's ratio, n • Poisson's ratio, n: n x z y z (Isotropic materials only) metals: n ~ 0.33 ceramics: n ~ 0.25 polymers: n ~ 0.40 Units: E: [GPa] or [psi] n: dimensionless –n > 0.50 density increases –n < 0.50 density decreases (voids form) Derivative Relationship 1 x x ( y z ) E Other Elastic Properties • Elastic Shear modulus, G: t M G t=Gg • Elastic Bulk modulus, K: DV P = -K Vo g M P P K DV P Vo • Special relations for isotropic materials: E G 2(1 n) simple torsion test E K 3(1 2n) P pressure test: Init. vol =Vo. Vol chg. = DV Plastic (Permanent) Deformation (at lower temperatures, i.e. T < Tmelt/3) • Simple tension test: Elastic+Plastic at larger stress engineering stress, s Elastic initially permanent (plastic) after load is removed ep engineering strain, e plastic strain Adapted from Fig. 6.10 (a), Callister 7e. Most metals – elasticity only continues until strains of about 0.005 Yield Strength, y • Stress at which noticeable plastic deformation has occurred. when ep = 0.002 tensile stress, y y = yield strength Note: for 2 inch sample e = 0.002 = Dz/z Dz = 0.004 in engineering strain, e p = 0.002 Adapted from Fig. 6.10 (a), Callister 7e. Tensile Strength, Tult • Maximum stress on engineering stress-strain curve. Adapted from Fig. 6.11, Callister 7e. Tult F = fracture or ultimate strength engineering stress y Typical response of a metal Neck – acts as stress concentrator strain engineering strain • Metals: occurs when noticeable necking starts. • Polymers: occurs when polymer backbone chains are aligned and about to break. Ductility • Plastic tensile strain at failure: Lf Lo x 100 %EL Lo smaller %EL Engineering tensile stress, s larger %EL Lo Ao Af Adapted from Fig. 6.13, Callister 7e. Engineering tensile strain, e • Another ductility measure: %RA = Ao - Af x 100 Ao Lf “Toughness” • Ability to absorb energy before fracturing • Approximated by the area under the stress-strain curve. Engineering tensile stress, s small toughness (ceramics) large toughness (metals) very small toughness (unreinforced polymers) Adapted from Fig. 6.13, Callister 7e. Engineering tensile strain, Brittle fracture: elastic energy Ductile fracture: elastic + plastic energy Note: Not fracture toughness, not notch toughness e Effect of Temperature on “Toughness” Figure 6.14 from text: Engineering stress-strain for iron at three temperatures Resilience, Ur • Ability of a material to store energy – Energy stored best in elastic region Ur y 0 d If we assume a linear stress-strain curve this simplifies to 1 Ur @ y y 2 Adapted from Fig. 6.15, Callister 7e. Elastic Strain Recovery Adapted from Fig. 6.17, Callister 7e. True Stress & Strain S.A. changes when sample stretched • True stress • True Strain F Ai ln i o s1 e ln 1 e Adapted from Fig. 6.16, Callister 7e. Hardening • An increase in y due to plastic deformation. large hardening y 1 y small hardening 0 • Curve fit to the stress-strain response (flow curve): K is stress at = 1 K “true” stress (F/A) n Strain hardening coefficient: n = 0.15 (some steels) to n = 0.5 (some coppers) “true” strain: ln(L/Lo) Strain hardening coefficient: slope of log-log plot Variability in Material Properties • Elastic modulus is material property • Critical properties depend largely on sample flaws (defects, etc.). Large sample to sample variability. • Statistics n – Mean – Standard Deviation xn x n 2 n x x i s n 1 where n is the number of data points 1 2