NSF-CRCD Chemicals from Biorenewables PI: Charles E. Glatz co

advertisement

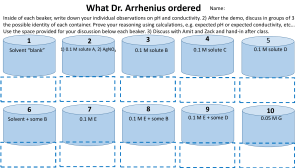

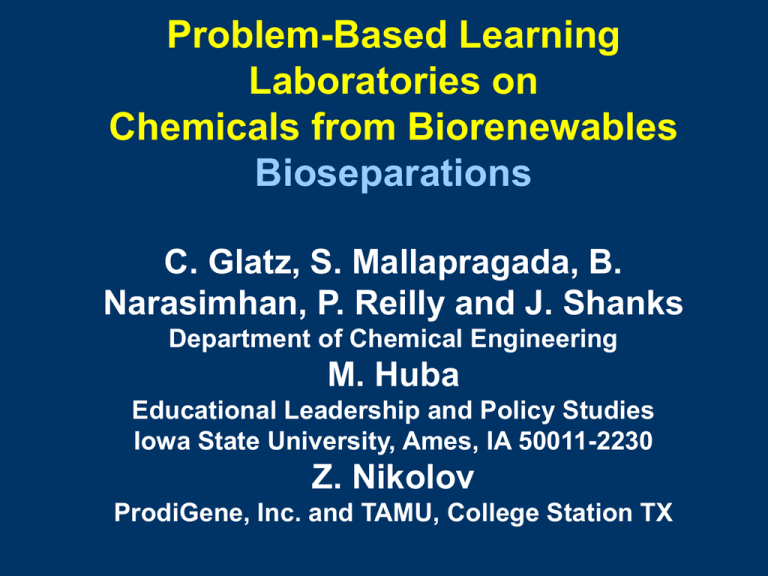

Problem-Based Learning Laboratories on Chemicals from Biorenewables Bioseparations C. Glatz, S. Mallapragada, B. Narasimhan, P. Reilly and J. Shanks Department of Chemical Engineering M. Huba Educational Leadership and Policy Studies Iowa State University, Ames, IA 50011-2230 Z. Nikolov ProdiGene, Inc. and TAMU, College Station TX Vision We have developed four 1-credit open-ended, multidisciplinary laboratory courses involving “Chemicals from Biorenewables”. These problem-based learning laboratories have been integrated with existing and new bioengineering-related ChE classes Target audience: – undergraduate (seniors) and graduate students in Chemical Engineering – undergraduate and graduate students in Biochemistry and Biophysics, Biology and Food Science. Motivation: Topic ChE evolving from a petrochemical-based to a biorenewables-based discipline. Examples: Product Indigo poly(lactic acid) Biopol 1,3 propanediol Species used Microbial Microbial Microbial/plants Microbial Company Genencor Cargill/Dow Monsanto DuPont Current ChE curriculum does not reflect this trend Introduce new courses to cover this new technology Motivation: Educational Problem-based learning – – – – Open-ended problems Learning-based approach Students direct learning of the topic Problems provide motivation for learning Multidisciplinary – Team-based approach ABET criteria – Life-long learning Curriculum Structure Four new 1-credit laboratories - each associated with an existing or new ChE undergraduate/ graduate level biotechnology related theory course Each laboratory course has one open-ended design project topic and list of desired outcomes Students work in teams of three - each team has a student with a biology/biochemistry background Opportunity for problem-based, studentdirected, multidisciplinary team-based learning Bioethics component General Lab Course Outline First two weeks: Common component for all the lab classes - Teach students statistics, bioethics, how to work in teams, literature searches, laboratory notebooks. Faculty member plays role of instructor with learning exercises in context of technical content of the course. Next three weeks: Literature review, coming up with plan for solving the problem, team roles, some laboratory training. Faculty member plays role of coach. Next nine weeks: Implementation of plan, experimental design. Faculty member plays role of coach Last two weeks: Wrapping up, written and oral presentations Description of Laboratory Courses Bioinformatics - (Spring 03: Reilly) - Development of bioinformatic and virtual reality techniques for investigating and predicting enzyme structure and function. Metabolic Engineering - (Spring 02: Shanks) Combination of experimental methods with mathematical analysis of the metabolism of ethanol fermentation from yeast. Bioseparations - (Fall 02: Glatz) - Development of a process for recovering a recombinant protein expressed in corn germ. Tissue Engineering - (Fall 02: Mallapragada, Narasimhan) - Development of a bioreactor to cultivate bioartificial skin in vitro on suitable biodegradable polymer scaffolds Acknowledgments NSF Combined Research and Curriculum Development Grant EEC 0087696 Barry Lamphear and Susan??, Prodigene, Inc. for assistance with ELISA. Nicolas Deak, Erin Denefe and Tom Mathews for their presentation. Summer research crew of Danielle McConnell, Jim Kupferschmidt, Yandi Dharmadi, Zhengrong Gu, Maureen Griffin Tutors Todd Menkhaus and Kevin Saunders Brazzein Purification ChE 562 12/06/02 Goal Objectives: • Develop a separation process to recover Brazzein from transgenic corn • Purity must be > 80% of total protein content • Salt content in final product must be less than 0.01M Starting material: • Defatted transgenic corn germ meal with some endosperm contamination. Initial brazzein concentration 250 g per gram of meal Brazzein molecular structure: Brazzein Information • • • • • • Small molecule 6500 Da Thermo-stable 32-82 C Water Soluble pH= 3.6, 4, and 7 pI=5.4 Water solubility will be at least 50 mg/ml. Two different types of brazzein. Type II twice as sweet as Type I. Experimental Procedures Transgenic Corn Germ Extraction Cation Exchange Chromatography Size Exclusion Purified Brazzein Size Exclusion Extraction Variables Protein/Water Ratio = 1g/6 mL, temperature = 23 pH= 4.0-5.5 Salt concentration =50 NaOAc: 100 mM NaCl Mixing time of 45 minutes Protein extraction vs pH Protein concentration (ug/mL) • • • • 1800 1559.5 1600 1357.9 1400 1200 1000 800 594.4 690.7 600 400 200 0 pH 4 pH 4.5 pH 5 pH 5.5 Size Exclusion HPLC • The objective for this test was to asses whether simple membrane filtration was applicable in this case. • The Brazzein rich extract (pH 4) is eluted in a Size Exclusion HPLC • Elution conditions: – pH 4.0 – NaAc Buffer ( NaAc 20mM, NaCl 30 mM) • A standard elution curve was run in parallel, using known MW markers. HPLC Standard Curve Molecular Weight (kD) 750 500 250 0 10 12 14 16 18 20 Time (min) Molecular Weight = 147416 exp(-0.4751* Time) R2 = 0.9404 22 24 HPLC Results Contaminant Brazzein 2.91 kDa 6.5 kDa 22.8 min. 21.1 min. HPLC Conclusions • A direct membrane filtration of our Brazzein rich extract is not applicable in this case • The overlapping contaminant protein peak is important enough to try some other means to purify our product Cation Exchange Chromatography • Goal: Separate brazzein from the 2.91 kDa contaminant • Cation exchange successful removing brazzein from yeast cells (Irwin) • Resin type: SP (sulphopropyl) Sepharose Fast Flow • Elute with linear salt gradient 0-1 M NaCl Cation Exchange Setup • Column: SP Sepharose fast flow resin • Length = 8 cm • Diameter = 1 cm • Volume = 6.28 mL • Buffers: • A = 20 mM NaOAc, pH 4.0 • B = Buffer A + 1.0 M NaCl • Operation: • Flowrate = 1.0 mL/min Cation Exchange for Pure Brazzein Sample 40 g/mL pure brazzein in DI water Equilibration of column with Buffer A Load of 10 column volumes Gradient elution from 0%-100% Buffer B in 15 column volumes • Isocratic flow of 100% buffer in 5 column volumes • • • • Cation Exchange for Corn Germ • Sample 20 g + 120 mL Buffer A • Mixed 40 min, centrifuged 30 min. (15000 rpm), and filtered (0.22 m CA) • Equilibration of column with Buffer A • Load of 5 column volumes • Gradient elution from 0%-100% Buffer B in 15 column volumes • Isocratic flow of 100% buffer in 5 column volumes Cation Exchange Results • Section of concern 27-43 minutes after elution begins (30-45% Salt gradient) • Estimate fold of purification • assuming no nonprotein UV280 adsorbing materials • Perform experiment to determine molecular weight of material in this section 1.8 100 1.6 Light Absorbance (UV) 1.2 Pure Brazzein 60 Nontransgenic Corn 1.0 Salt Gradient 0.8 40 0.6 0.4 20 0.2 0.0 0 -3 -2 -1 0 Time (hr) 1 2 Salt Gradient (% 20 mM NaOAc) 80 1.4 1.8 100 1.6 80 1.2 Absorbance Fraction Pure Brazzein 60 Transgenic Corn 1.0 Salt Gradient 0.8 40 0.6 0.4 20 0.2 0.0 -3.0 0 -2.5 -2.0 -1.5 -1.0 -0.5 Time (hr) 0.0 0.5 1.0 1.5 Salt Gradient (% 20 mM NaOAc) 1.4 Conclusions: • Cationic exchange chromatography is more effective (72 %) • This is not enough to comply with our specifications • After analyzing SDS-PAGE electrophoresis results we decided to do a size exclusion • Expected results will be within specifications Questions? Do you have any suitable problem? Impact Make ChE education more relevant for our undergraduate students Teach students – problem-based learning techniques – develop their metacognitive abilities – life-long learning Coupling these educational techniques with valued new technologies Integrate some of these new experiments in a non open-ended manner into the required ChE undergraduate laboratories Assessment Self- and instructor-assessment using – Teamwork rubric – Design rubric – Written report rubric – Oral presentation rubric Curriculum Structure Biochemical Engineering Metabolic Engineering Upstream Processing Microbial Engineering Lab Bioinformatics Lab Bioseparations Polymeric Biomaterials Downstream Processing BioSeparations Lab Product Development Tissue Engineering Lab