Design Review ppt#1

ARD, Carderock Division, Bayview,ID

Project Professors: Dr. Herb Hess & Dr. Brian

Johnson

Summer Research Presentation

August 27th, 2008

Authors:

Jarred Coulter

Vishu Gupta

Zane Sapp

•

•

•

•

•

Summary-Spring 2008

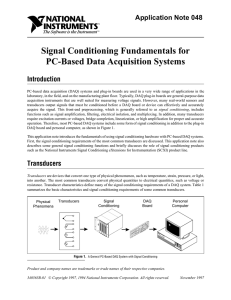

National Instruments Data

Acquisition System (DAQ)

Sensors

System Applications and

Capabilities

Future Work-Fall 2008

2

•

•

•

•

Statement of Work

Deliverables

DAQ Solutions Researched

Potential Design Issues

3

•

•

•

•

•

•

Designing a data acquisition system (DAQ) that will interface with the existing systems on the AESD.

Manage and display data from sensors for voltages, currents, and temperatures from the propulsion system and UPS system batteries.

Correlate above data with the GPS data available.

Graphical display: real-time and static

On board data storage buffer.

Expandable Architecture

4

•

Report of Potential design solutions

•

Recommended System Selection Report

•

Working prototype

•

Report on Final Configuration

5

•

•

•

Iotech LogBook Stand Alone, Intelligent

PC-Based Data Acquisition Systems

Models 300 and 360.

Iotech MultiScan 1200.

NI Compact DAQ Series

6

•

Making sure these Systems can operate in an ungrounded system.

•

External Multiplexing controlled by the DAQ to allow for large number of inputs per channel.

•

The 500V Channel to Channel Isolation or common mode voltage rating is inadequate for high voltage from batteries.

7

•

System Architecture Overview

•

Hardware

•

Software

8

9

•

•

•

•

•

•

M-Series Data Acquisition Device

1.25 Ms/s

Up to 280 Channels per DAQ Device with Current

Configuration

16-Bit ADC Resolution

•

•

•

MXI-Express Connection

110 Mb/s and up to 250 Mb/s Transfer Rate

PC and Laptop Compatible

High Bandwidth Allows for Large Channel Count through

Multiple Chassis

•

•

SCXI/PXI

Hundreds of Input Modules for wide range of Application

Rugged Chassis for Industrial Applications

10

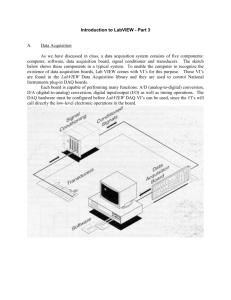

DATA ACQUISITION SYSTEM

FROM NATIONAL

INSTRUMENTS

SYSTEM COMPONENTS

2.

3.

1.

4.

5.

6.

PXI/SCXI Combination

Chassis

MXI Express Link

M-Series DAQ and

PXI/SCXI Chassis

Controller

32-Channel Input

Module/Multiplexer

I/O Connector M-Series

DAQ (Not Shown)

Cast Screw Terminal Block for SCXI-1104C with Cold

Junction Compensation

11

•

LabVIEW 8.2

•

LabVIEW Signal Express

•

Measurement and Automation Controller

(MAX)

12

•

•

•

•

Built in VI’s for Data Acquisition, Analysis,

Storage, Display

Mathscript capabilities

Stores all data in an ASCII text file called

LabVIEW Measurement File (LVM)

DAQmx and DAQ Assistant for Easier

Programming

13

•

•

•

No Programming Data Acquisition

Export Data Directly to Excel Spreadsheet or Text Editor

Real-Time Display

14

•

•

Manage all the National Instruments

Hardware

Automatically Detects all devices connected to system

15

• Isolation Amplifier Type Voltage

Transducers

• Designed my Own

• Cost Around 5 Dollars

• Hall Effect Voltage Transducers

• Capable of accurately handling very high voltages

• Cost around $250 per unit when bought in Bulk

• LEM Current Transducers

• Accurately Measure wide range of Currents

• Cost around $400 per unit when bough in Bulk

16

17

18

19

LEM CV 3-500 FEATURES

•

•

•

•

•

Closed Loop Hall Effect

Voltage Transducer

Measuring range: 0 to 500 V

Output Voltage: 0 to 10 V

(Max)

Supply Voltage: ± 15 VDC

± 0.2% Accuracy at T

A

=25 C

20

LEM DC-C10 FEATURES

•

•

•

•

DC Current Transducer

3 Jumper Adjustable

Ranges: 5, 10, 20 Amp

Max

Supply Voltage: 20-50

VDC

±1% Accuracy at

T

A

=25 C

21

•

•

•

•

•

•

Monitoring of Propulsion System and UPS

System Battery Banks

Battery Status

•

• Voltage

Temperature

•

Charge Monitoring

Possible Feedback Control for Charging Schemes

•

Fuel Cell Monitoring

Harmonics Measurement and Analysis

Measuring waveforms

LabVIEW for Transforms and Harmonic Analysis

22

•

•

•

LabVIEW Programming For:

Data Management

•

•

• Storage

Display

Analysis

•

•

Switching Scheme for Controlling Sensors

Sensors Powered by Batteries

Need to be able to turn them off when not acquiring data

• GPS Interface

• Time Stamping

• Link time to Master Clock

• Location Stamping

• Onboard Data Storage Buffer

23

• Testing

• Determine Latency for Real Time

• Determine Power Consumption

• Calculate Cost Per Channel for Multiple Chassis

Configuration

• Determine Bandwidth for Multiple Chassis

Configuration

24

•

•

•

•

•

•

•

Spring 2008

SOW

Deliverables

DAQs

Design Issues

Summer 2008

• NI DAQ and LabVIEW Software

• Sensors

Fall 2008

• LabVIEW Programming

• Sensor power and control

• Onboard storage

• Testing

25

ONR

Alan Griffitts

Frank Jurenka

Karl Sette

MRCI

Dr. Brian K. Johnson

Dr. Herbert L. Hess

Karen Cassil

Research Group

John Finely

Leo Lucklose

Justin Schlee

Sunan Huang

James Randall

26