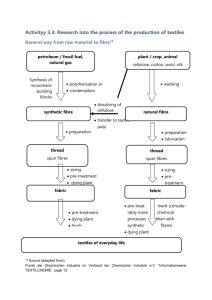

The Spinning Process

advertisement

Year 9 Textiles Miss Rollo There are 3 different ways to produce synthetic fibres. They are: •Dry Spinning •Wet Spinning •Melt Spinning 1.The polymer chips are dissolved in a solvent which makes them become a viscous solution (Having a thick, sticky consistency between solid and liquid). 2. The mixture is pumped from the hopper through the spinneret. 3. Warm airs draughts evaporate the solvent making the filaments coagulate. (to change from a fluid into a thickened mass) 4. The filaments are drawn and stretched between 2 sets of rollers 5. The filament is wound onto bobbins Fibres that are produced using Dry spinning are; Acetate, Lycra, Acrylic Is the oldest man made fibre manufacturing method. 1. Raw materials are dissolved by chemical to form a viscous solution. 2. The mixture is pumped through the spinneret. 3.Filament is spun into an Acid bath. 4.Yarn solidifies when coagulated by the acid in the bath. 5. Drawing and stretching is done by rollers 6. Filaments is wound onto bobbins Fibres that are produced using Wet spinning are; Viscose Rayon & Acrylic. Is the simplest method of obtaining the fibre. 1. The polymer chips are melted at the base of the hopper. 2. The pump forces the viscous solution through the spinneret. 3. The streams of molten are then coagulated into filaments by cool air. 4. The filaments are then drawn onto rollers with the last set moving faster than the first set. This stretches the filament. 5. The filament is wound onto a bobbin. Fibres that are produced using Melt spinning are; Nylon & Polyester.