Scott - University of Guelph

advertisement

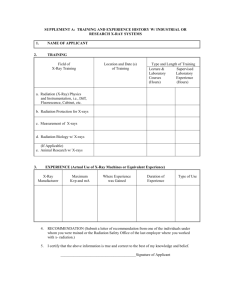

X-ray Lithography physical synthesis of nanostructures 20 nm 60 nm Chen et al., Electrophoresis, 2001 Scott Allen Physics Department University of Guelph Outline What is lithography? What are x-rays? x-ray lithography (XRL) production of x-rays x-ray interactions mask production Summary Lithography the exposure and development of a pattern in a radiation sensitive film (called a resist) – typically a polymer lithography is generally followed by a process which transfers the pattern from the resist to a substrate via etching, growth of a material in the interstices of the resist , or doping What are x-rays? Wilhelm Conrad Roentgen (1845-1923) discovered an unknown ray in 1895 (X-ray) http://www.xray.hmc.psu.edu/rci/ss1/img0003.JPG experimenting with evacuated tubes that he would fill with specific gases and then pass electricity through Roentgen found that despite shrouding the tube in black paper (as it let off a glow similar to our incandescent bulbs) it somehow caused a barium platinocyanide-coated screen to glow won the first Nobel prize in physics in 1901 http://pt.wikipedia.org/wiki/Imagem:Roentgen-x-ray-von-kollikers-hand.jpg Where are x-rays? x-rays are light (l = 10 nm to 0.01 nm) http://lasp.colorado.edu/cassini/images/Electromagnetic%20Spectrum.jpg x-ray interactions x-rays interact with matter through the excitation or ionization of atomic electrons absorption of high energy x-rays causes the creation of photoelectrons (core shell holes) but does not lead directly to resist modification Cerrina, J Phys D, 2000 relaxation is what leads to material modifications energy release of a higher lying electron via x-ray fluorescence Auger effect – higher lying electron transfers energy to another atomic electron, which is then ejected eds. Suzuki, et al., “Sub-Half-Micron Lithography for ULSIs”, 2000 photoelectrons and auger electrons are responsible for modification of resists Producing x-rays – synchrotron radiation uses a magnetic field to cause an electron beam to follow a circular orbit at velocities near the speed of light, the orbiting electron’s emitted radiation will become sharply peaked in the forward direction Wilson et al., IBM J Res Develop, 1993 capable of providing continuous source of soft and hard x-rays Synchrotron Wilson et al., IBM J Res Develop, 1993 other methods of x-ray production exist (electron beam bombardment, laser plasma, etc.) plasma debris, insufficient intensity, blur, etc. x-ray lithography is a 1 X lithography (shadow) technique D. L. Spears and H. I. Smith, “High-Resolution Pattern Replication Using Soft X-Rays,’’ Electron. Lett. 8, 102 (1972). traditional lens systems are unavailable (no demagnification) therefore mask features must be of the order of the feature dimensions that are required therefore great effort must be put into creating high precision masks and properly aligning them XRL resolution is determined mainly by Fresnel diffraction and scattering of secondary electrons in the resist x-ray masks support glass substrate Peckerar, Proc. IEEE, 1993 must be transparent to x-rays (low atomic number) must also be rigid to prevent distortion silicon-nitride absorber must be absorbant to x-rays (high atomic number) Au, W, Ta or one of their alloys concerns: non-uniformity of stress in x-ray absorber, pattern placement error in the E-beam lithography, damage due to x-ray irradiation Production precise gap must be maintained beam scanned over mask fresnel diffraction 2 f = w /lg f – fresnel number w – feature size l – x-ray wavelength g – gap spacing 100 nm features require (l = 1 nm, g = 10 mm with f = 1) Cerrina, J Phys D, 2000 Summary synchrotron production of x-rays is the most favorable mask production seems to be the limiting step in the technology (no demagnification optics possible) expensive to produce minimum feature size is dependent upon a number of factors materials used, wavelength of x-ray, gap spacing Future lithography technology driven by semiconductor manufacturing INTEL’s lithography roadmap proposes the extension of extreme ultra violet (EUV – 13.5 nm) lithography down to 45nm feature generation in order for x-ray lithography to become industrially relevent and not purely the domain of research it must become economically favorable at feature sizes below 45nm this means a deviation from the exact technology described here but using similar principles the 20 nm regime is accesible Kitayama et al., J Vac Sci Technol B, 2000 Khan et al., J Vac Sci Technol B, 2001 thanks Any questions? mask fabrication Cerrina, J Phys D, 2000 www.medical.philips.com/main/products/xray/assets/images/rad/unique/DR_L_spine_02_lar http://www.thebritishmuseum.ac.uk/science/images/femurc14.gif