Statics and Strength of Materials

advertisement

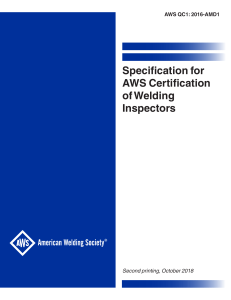

NE 127 – Codes, Standards, and Regulations American Welding Society INSTRUCTOR: Chattanooga State CC American Welding Society (AWS) - General Information • Founded in 1919 • Goal to “advance the science, technology and application of welding and related joining disciplines” • Headquartered in Miami since 1971 (originally based in NYC) • 55,000+ members worldwide – Engineers, scientists, educators, researchers, welders, inspectors, executives, sales associates, etc. • 160 AWS-developed codes, recommended practices, and guides published under ANSI procedures Structural Welding Code, D1.1 • Covers the requirements for the design of welded connections for building structures and bridges • First issued in 1972 • One of the most consulted codes in the world • Divided into 10 sections and 9 appendices – – – – – Section 1: General Provisions Section 2: Rules for design of welded connections Section 3: Requirements for workmanship Section 4: Requirements for weld technique Section 5: Requirements for welding procedure and welder qualifications Structural Welding Code, D1.1, Continued – Section 6: Requirements for Inspection (visual only, unless specified) – Section 7: Additional requirements for strengthening and repairing existing buildings and structures – Section 8: Additional requirements for design of new buildings – Section 9: Additional requirements for design of new bridges – Section 10: Additional requirements for design of new tubular structures Other AWS Codes Applicable to NDT – QA/QC • • • • • A2.1 – Welding Symbols Chart A3.0 – Standard Welding Terms and Definitions B1.10 – Guide for Nondestructive Examination of Welds B1.11 – Guide for the Visual Examination of Welds B5.1 – Specification for the Qualification of Welding Inspectors • QC1 – Standard for AWS Certification of Welding Inspectors Qualification and Certification of Weld Inspectors • Qualification and Certification Committee of the AWS formed in 1973 • AWS QC1 first published in 1975 – More than 55,000 individuals have the requirements for certification as a weld inspector (as of 2007) • Committee divided into two freestanding committees in 1996 – one devoted to qualification of inspectors – one to certification of inspectors Qualification vs. Certification Definitions per AWS B5.1: • Qualification – Demonstrate training, skill, knowledge and experience required for personnel to perform the duties of a specific job or function typically demonstrated by passing a performance test • Certification – The act of determining, verifying, and attesting in writing to the qualification of personnel in accordance with specified requirements. QC1 – Standard for AWS Certification of Welding Inspectors • Defines the requirements and program for the AWS to certify welding inspectors • Requires documentation of: – Experience – Satisfactory completion of an examination • Determines general knowledge of welding inspection and related technical areas – not a practical exam – Proof of visual acuity QC1 – Scope • Establishes the requirements for AWS certification of welding inspection personnel: how personnel are certified, and principles of conduct and practice by which certification may be maintained • Meets or exceeds requirements of AWS B5.1 • 3 levels of certification: – Senior Certified Welding Inspector (SCWI) – Certified Welding Inspector (CWI) – Certified Associate Welding Inspector (CAWI) Levels of Certification Reference AWS B5.1 and QC1: Level of Certification Minimum Education Requirements SCWI High School or GED Work Experience* 15 Years Near/Color Other Vision Acuity Requirements Required 6 Years Experience as a CWI High School or 5 Years Required GED High School or CAWI 3 Years Required GED *Subtract 2 years for Associate’s Degree, 1 year for vocational school; CWI Add years (varies) for 8th grade education or less QC1, B5.1 – Definitions • Endorsement – Indication of an additional skill documented in writing and added to one’s certification credentials • Nondestructive examination – the act of determining the suitability of some material or component for its intended purpose using techniques that do not affect its serviceability • Quality assurance (QA) – all the planned and systematic activities implemented within the quality system, and demonstrated as needed, to provide adequate confidence that an entity will fulfill requirements for quality QC1, B5.1 – Definitions, Continued • QA audit – Systematic and independent examination to determine whether quality activities and related results comply with planned arrangements and whether these arrangements are implemented effectively and are suitable to achieve objectives • QA surveillance – Continued monitoring and verification of the status of an entity and analysis of records to ensure that specified requirements are being fulfilled • Quality control (QC) – Operational techniques and activities that are used to fulfill requirements for quality Functions of an SCWI • • • • • Train, supervise, and evaluate WIs, CAWIs, and/or NDE personnel Prepare inspection procedures Review and interpret joining procedures Conduct audits of vendors Ensure that work performed and records maintained conform to the requirements of the applicable standards and other contract documents • Certify the qualification of welders to various codes and specifications • Develop safety procedures, QA plans, project plans, and training programs • Perform skills as listed in Table I of AWS B5.1 Functions of a CWI • Ensure that work performed and records maintained conform to the requirements of the applicable standards and other contract documents • Supervise and train AWIs • Conduct audits of vendors • Perform skills as listed in Table I of AWS B5.1 Functions of a CAWI • Perform inspections under the direct supervision (within visible and audible range) of a SCWI or CWI • SCWI or CWI responsible for certifying that welded assemblies conform to workmanship and acceptance criteria • Perform skills as listed in Table I of AWS B5.1 SCWI Written Examination Requirements • Must pass 200 question exam with a minimum score of 72% • B5.1 specifies the breakdown of the types of questions to be asked – Minimum of 10% on NDE fundamentals techniques, and applicability (VT, PT, MT, RT, and UT) – Minimum of 5% on safety programs and procedures • May retake exam up to 2 times with one year of original test date CWI Written Examination Requirements • Must pass three separate parts on: 1) fundamentals, 2) practical application, and 3) code application, with a minimum score of 72% on each part • If achieve an overall composite score of 72%, but earn a score less than 72% on any particular part, the failed part(s) may be retaken • B5.1 again specifies the breakdown of the types of questions to be asked for each part of the exam • Applicant may specify the code to which they are to be tested • May retake exam up to 3 times within three years of original test date (any more than 1 retest requires additional training) CAWI Written Examination Requirements / Visual Acuity • Must pass same exam as required for CWIs, but with a minimum score of 60% • CAWI certification may not be renewed – May be upgraded to CWI status once experience requirements met, IF exam passed with a minimum score of 72% – Certification expires after 3 years • Visual Acuity (for all levels of certification) – Must pass near vision and color vision exams (administered by medical personnel) – Near vision acuity considered essential to the proper performance of welding examination – Per B5.1 - ”Failure to meet vision requirement shall be a failure to meet this standard” Code of Ethics, Rules of Conduct, and Practice • Individual with SCWI, CWI, and CAWI must maintain the highest levels of: – Integrity – Responsibility to the public • Perform duties in a conscientious and impartial manner to the full extent of the inspector(s) moral and civic responsibility and qualification • SCWIs, CWIs, and CAWIs must also avoid conflicts of interest • Failure to abide by the above may result in suspension, refusal to renew, or revocation of certification Renewal Requirements • SCWI and CWI certifications may be renewed every 3 years if actively working as an inspector • After 9 years (and every 9 years thereafter), recertification must be either by exam or satisfaction of continuing education – Minimum of 80 PDHs (professional development hours) required in the 9-year period – If an SCWI fails the exam, all certification is revoked