Summary - Northrop Grumman Corporation

advertisement

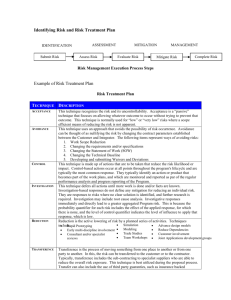

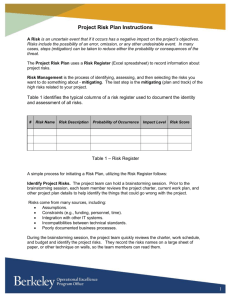

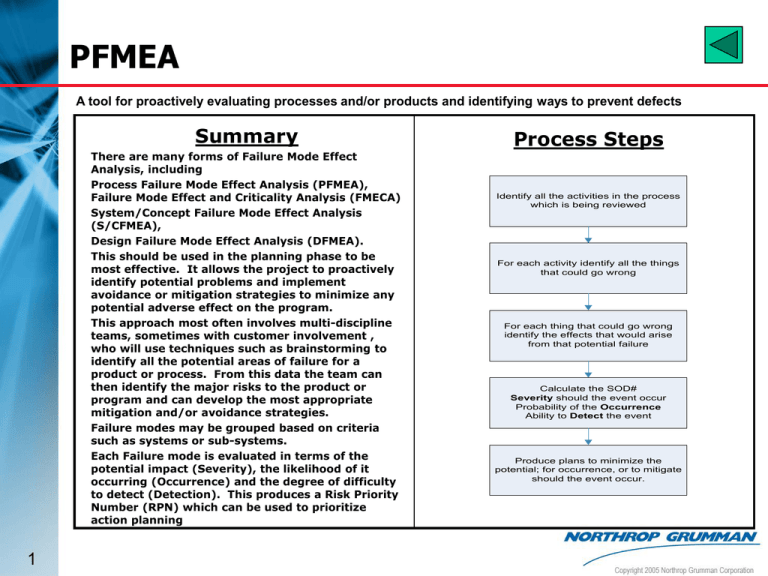

PFMEA A tool for proactively evaluating processes and/or products and identifying ways to prevent defects Summary There are many forms of Failure Mode Effect Analysis, including Process Failure Mode Effect Analysis (PFMEA), Failure Mode Effect and Criticality Analysis (FMECA) System/Concept Failure Mode Effect Analysis (S/CFMEA), Design Failure Mode Effect Analysis (DFMEA). This should be used in the planning phase to be most effective. It allows the project to proactively identify potential problems and implement avoidance or mitigation strategies to minimize any potential adverse effect on the program. This approach most often involves multi-discipline teams, sometimes with customer involvement , who will use techniques such as brainstorming to identify all the potential areas of failure for a product or process. From this data the team can then identify the major risks to the product or program and can develop the most appropriate mitigation and/or avoidance strategies. Failure modes may be grouped based on criteria such as systems or sub-systems. Each Failure mode is evaluated in terms of the potential impact (Severity), the likelihood of it occurring (Occurrence) and the degree of difficulty to detect (Detection). This produces a Risk Priority Number (RPN) which can be used to prioritize action planning 1 Process Steps Identify all the activities in the process which is being reviewed For each activity identify all the things that could go wrong For each thing that could go wrong identify the effects that would arise from that potential failure Calculate the SOD# Severity should the event occur Probability of the Occurrence Ability to Detect the event Produce plans to minimize the potential; for occurrence, or to mitigate should the event occur.