The Basic Seven (B7) Tools of Quality

advertisement

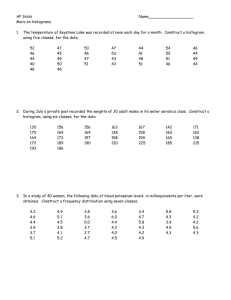

The Basic Seven (B7) Tools of Quality "As much as 95% of quality related problems in the factory can be solved with seven fundamental quantitative tools." - Kaoru Ishikawa By Zaipul Anwar Business & Advanced Technology Centre, Universiti Teknologi Malaysia What are the Basic Seven Tools of Quality? Fishbone Diagrams Histograms Pareto Analysis Flowcharts Scatter Plots Run Charts Control Charts Where did the Basic Seven come from? Kaoru Ishikawa Known for “Democratizing Statistics” The Basic Seven Tools made statistical analysis less complicated for the average person Good Visual Aids make statistical and quality control more comprehendible. The Basic Seven (B7) Tools of Quality Fishbone Diagrams No statistics involved Maps out a process/problem Makes improvement easier Looks like a “Fish Skeleton” Fishbone Diagram Overview (1 of 2) Definition Use within organizations Uses Ishikawa benefits Creation of the Diagram Steps 1-9 Fishbone Diagram Overview (2 of 2) Example Service example Exercise Ham Industries Fishbone (Cause and Effect or Ishikawa) Diagrams (1 of 4) Named after Kaoru Ishikawa Japanese Quality pioneer Resembles skeleton of a fish Focus on causes rather than symptoms of a problem Emphasizes group communication and brainstorming Stimulates discussion Fishbone (Cause and Effect or Ishikawa) Diagrams (2 of 4) One of Seven basic tools of Japanese Quality Leads to increased understanding of complex problems Visual and presentational tool Fishbone (Cause and Effect or Ishikawa) Diagrams (3 of 4) Typically done on paper or chalkboard Recently some computer programs have been created to make Fishbone Diagrams Ishikawa Environment Use in Organizations (1 of 2) Can be used to improve any product, process, or service Any area of the company that is experiencing a problem Isolates all relevant causes Use in Organizations (2 of 2) Helps bring a problem into light Group discussion and brainstorming Finds reasons for quality variations, and the relationships between them Creating Fishbone Diagrams (1 of 4) • As a group: 1. Establish problem (effect) -state in clear terms -agreed upon by entire group 2. Problem becomes the “head” of the fish -draw line to head (“backbone”) Creating a Fishbone Diagram (2 of 4) 3. Decide major causes of the problem - by brainstorming - if the effect or problem is part of a process the major steps in the process can be used 4. Connect major causes to backbone of the fish with slanting arrows Creating a Fishbone Diagram (3 of 4) 5. Brainstorm secondary causes for each of the major causes 6. Connect these secondary causes to their respective major causes 7. Repeat steps 5 & 6 for sub-causes dividing with increased specificity - usually four or five levels Creating a Fishbone Diagram (4 of 4) 8. Analyze and evaluate causes and sub-causes -may require the use of statistical, analytical, and graphical tools 9. Decide and take action Example (1 of 4) Step 1 & 2: (“backbone”) Poor Service (“head”) Example (2 of 4) Step 3 & 4: Appearance Responsiveness Poor Service Attention Reliability Example (3 of 4) Step 5, 6, & 7: Responsiveness Appearance time equipment personnel courtesy Attention facility Poor Service accuracy One on one service dependability Reliability Example (4 of 4) Step 8 & 9: Use tools to analyze and evaluate causes Pareto diagrams, charts, and graphs Statistical analysis for causes in processes Decide and take action Use fishbone diagram, analysis and evaluations to find causes that can be fixed Take action to eliminate and fix problem causes Summary (1 of 3) • Fishbone Diagrams - visual diagram - resembles fish skeleton - identifies the causes of a problem (effect), and their relationships - created by Kaoru Ishikawa for Quality Management Summary (2 of 3) Organizational Uses Increases communication about problems Used to improve any product, process, or service Important part of quality management Summary (3 of 3) Creation of Fishbone diagrams Problem or effect is head of fish Identify major, secondary and tertiary causes, and attach to backbone identifying relationships Analyze and Evaluate results Act to fix the problem(s) Exercise Create a Fishbone (cause and effect, Ishikawa) Diagram for the following: Management at Ham Industries has noticed that the productivity of its workers is well below the standard. After interviewing its employees, it was noticed that a vast majority felt dissatisfied and unhappy with their work. Your boss has asked you and a group of your peers to find the causes of worker dissatisfaction . Include all possible causes to at least the secondary level. Bibliography //home.t-online.de/home/kfmaas/q_ishika.html www.zi.unizh.ch/software/unix/statmath/sas/sasdoc/qc /chap17/sect1.htm www.dti.gov.uk/mbp/bpgt/m9ja00001/m9ja0000110.htm l Foster, S. Thomas. Managing Quality: An Integrative Approach. 2001, Prentice-Hall The Basic Seven (B7) Tools of Quality Histograms Bar chart Used to graphically represent groups of data Overview 1) 2) 3) 4) 5) 6) What is a Histogram? What are some possible uses for a Histogram? Where did the Histogram come from? How do Histograms work? A real world example. An exercise. What is a Histogram? A Histogram is a variation of a bar chart in which data values are grouped together and put into different classes. This grouping allows you see how frequently data in each class occur in the data set. What is a Histogram (cont.) Higher bars represent more data values in a class. Lower bars represent fewer data values in a class. On the next slide is an example of what a Histogram looks like. Example of a Histogram Uses for a Histogram A Histogram can be used: to display large amounts of data values in a relatively simple chart form. to tell relative frequency of occurrence. to easily see the distribution of the data. to see if there is variation in the data. to make future predictions based on the data. Where did the Histogram Come From? The Histogram was first implemented by Kaoru Isikawa, one of Japans’ most renowned experts on quality improvement. Isikawa spent his life trying to improve quality in Japan. Where did the Histogram Come From? (cont.) His major contributions to quality improvement are known as the basic seven tools of quality. Included in his basic seven tools of quality is the Histogram. How do Histograms Work? First, you need need to pick a process to analyze. Next, you need a large amount of data, at least 100 data values so that patterns can become visible. Then, you need to assemble a table of the data values that you collected with regards to frequency of data values. How do Histograms Work? (cont) Next, you need to calculate some statistics for the Histogram, including: mean, minimum, maximum, standard deviation, class width, number of classes, skewness, and kurtosis. Then, you actually create the Histogram using these statistics. How do Histograms Work? (cont) After you have created a Histogram, it will take one of five shapes: Normal Distribution: How do Histograms Work? (cont) Positively Skewed: Negatively Skewed: How do Histograms Work? (cont) Bi-Modal Distribution: Multi-Modal Distribution: How do Histograms Work? (cont) Once your Histogram is complete, you can analyze its shape, as well as the statistics that you came up with. This analysis will help you to make better decisions toward quality improvements. Constructing a Histogram From a set of data compute sum mean (x) Max Min Range (max-min) Constructing a Histogram Use range to estimate beginning and end Calculate the width of each column by dividing the range by the number of columns Range # of Columns = Width Acme Pizza Example Let’s say the owner wants a distribution of Acme’s Thursday Night Sales Data Set from last Thursday(slices) 02122413121224341432232122122142212122121212121 21222121211222314223222123224224412223221224212 421721223121121222122121222424 Acme Pizza Example Mean = 2.032258 Max = 7 Min = 0 Range = 7 Question For 7 columns what would the width be? Range/Columns=7/7=1 slice Acme Pizza Example Histogram 65 70 60 50 40 33 30 20 8 10 12 0 0 1 5 6 7 0 1 2 3 4 Slices of Pizza Constructing a Histogram How is this helpful to Acme? 2 slices of pizza most common order placed Distribution of sales useful for forecasting next Thursday’s late night demand If you were an Acme manager how could you apply this information? The Basic Seven (B7) Tools of Quality Pareto Analysis Very similar to Histograms Use of the 80/20 rule Use of percentages to show importance Pareto Analysis, how to use it 1. Gather facts about the problem, using Check Sheets or Brainstorming, depending on the availability of information. 2. Rank the contributions to the problem in order of frequency. 3. Draw the value (errors, facts, etc) as a bar chart. 4. It can also be helpful to add a line showing the cumulative percentage of errors as each category is added. This helps to identify the categories contributing to 80% of the problem. 5. Review the chart – if an 80/20 combination is not obvious, you may need to redefine your classifications and go back to Stage 1 or 2. Acme Pizza (Example 1) Slices 0 1 2 3 4 5 6 7 Frequency 1 33 65 8 12 0 0 1 % .3 13.09 25.79 3.17 4.76 0 0 .3 Acme Pizza (Example 1) The completed Pareto Analysis results in the following graph: 70 60 50 40 30 20 10 0 21 1 2 43 34 75 56 Slices of Pizza 67 Acme Pizza (part 2) Critical Thinking How does the Pareto Analysis differ from the Histogram? How can this be a useful tool to the Acme boss? A series of Pareto charts drill down to more detail (Example 2) : Fault by Main Cause 1st level Analysis gives “Design” as main cause of failure 100 70 80 60 Percent 40 30 60 40 20 20 10 0 Count Percent Cum % n s ig De Design Faults 0 ild Bu er Oth 4 5.3 97.4 2 2.6 100.0 100 57 75.0 75.0 13 17.1 92.1 50 80 40 Percent Defect t en on mp Co Count Count 50 2nd level Analysis gives breakdown of “Design” 30 20 0 Count Percent Cum % 40 20 10 Defect 60 t ec nn Co le du Mo 21 36.8 36.8 s tor Mo ue q r To 10 17.5 54.4 t uc tar sd ld S Tran Co 8 14.0 68.4 le du Mo er IC AS 8 14.0 82.5 0 n atio libr Ca IOP 5 8.8 91.2 3 5.3 96.5 n Imo 2 3.5 100.0 The Basic Seven (B7) Tools of Quality Flowcharts A graphical picture of a PROCESS Process Decision The process flow Flowcharts Don’t Forget to: Define symbols before beginning Stay consistent Check that process is accurate Acme Pizza Example (Flowchart) Window (start) Take Customer Order Money? yes Get Pizza no Lockup Put More in Oven 2 Pies noAvailable? yes Time to close? no Take to Customer yes How can we use the flowchart to analyze improvement ideas from the Histogram? Window (start) Take Customer Order Money? yes Get Pizza no Lockup Put More in Oven 2 Pies noAvailable? yes Time to close? no Take to Customer yes Want some practice? Make a flowchart for: Taking a shower Cooking dinner Driving a car Having a party Creating a Flowchart Any other processes you can think of ? The Basic Seven (B7) Tools of Quality Scatter Plots 2 Dimensional X/Y plots Used to show relationship between independent(x) and dependent(y) variables Acme Pizza (Scatter Diagram) Minutes Cooking 10 45 30 75 60 20 25 Defective Pies 1 8 5 20 14 4 6 In this simple example, you can find the existing relationship without much difficulty but… Scatter Diagrams •Easier to see direct relationship 25 20 15 10 5 0 0 20 40 60 Time Cooking (minutes) 80 Scatter Diagrams As a quality tool What does this tell Acme management about their processes? Improvements? 25 20 15 10 5 0 0 20 40 60 Time Cooking (minutes) 80 The Basic Seven (B7) Tools of Quality Run charts Time-based (x-axis) Cyclical Look for patterns Run Charts Slices/hour 8 9 10 11 12 1 2 3 4 8 9 10 11 12 1 2 3 4 8 9 10 11 12 1 2 3 4 PM- AM PM- AM PM- AM Thursday Thursday Thursday Week 1 Week 2 Week 3 Time The Basic Seven (B7) Tools of Quality Control Charts Deviation from Mean Upper and Lower Spec’s Range Control Charts Upper Limit X Lower Limit Unacceptable deviation Control Charts Acme Pizza Management wants to get in on the control chart action •Average Diameter = 16 inches •Upper Limit = 17 inches •Lower Limit = 15 inches Acme example Control Charts Upper Limit 17 inches 16 inches=X Lower Limit 15 Inches Small Pie Acme example #50 Control Charts •Pies within specifications were acceptable •One abnormally small pie is “uncommon” •Should be examined for quality control Logical Order for B7 Tools Big Picture Flow Chart Data Collection Check Sheet Data Analysis Problem Identification Prioritization Histograms Cause & Effect Pareto Analysis Scatter Diagrams Control Charts Summary Basic Seven Tools of Quality Measuring data Quality Analysis “Democratized statistics” Bibliography Foster, Thomas. Managing Quality. An IntegrativeApproach. Upper Saddle River : Prentice Hall, 2001. Stevenson, William. “Supercharging Your Pareto Analysis.” Quality Progress October 2000: 51-55. “Dr Kaoru Ishikawa.” Internet “http://www.dti.gov.uk/mbp/bpgt/m9ja00001/m9ja0000110.html.” 16 February 2001. “Chemical and Process Engineering.” Internet. “http://lorien.ncl.ac.uk/ming/spc/spc8.htm.” 17 February 2001.