iii. analysis

advertisement

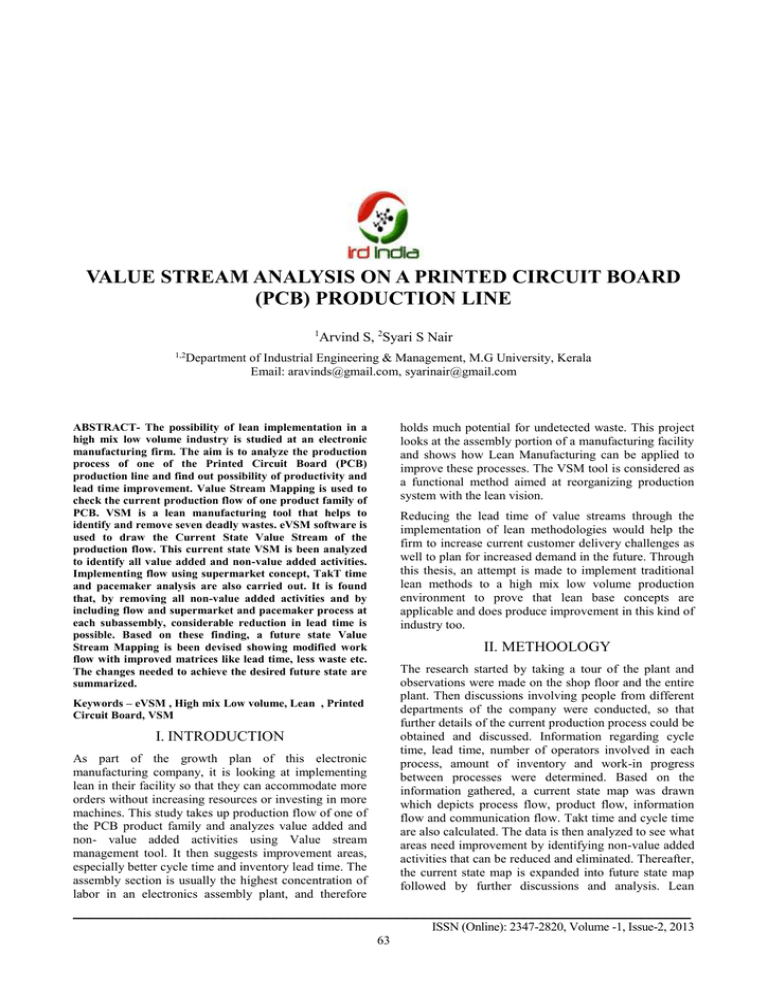

International Journal of Electrical, Electronics and Computer Systems, (IJEECS) _______________________________________________________________________ VALUE STREAM ANALYSIS ON A PRINTED CIRCUIT BOARD (PCB) PRODUCTION LINE 1 Arvind S, 2Syari S Nair 1,2 Department of Industrial Engineering & Management, M.G University, Kerala Email: aravinds@gmail.com, syarinair@gmail.com holds much potential for undetected waste. This project looks at the assembly portion of a manufacturing facility and shows how Lean Manufacturing can be applied to improve these processes. The VSM tool is considered as a functional method aimed at reorganizing production system with the lean vision. ABSTRACT- The possibility of lean implementation in a high mix low volume industry is studied at an electronic manufacturing firm. The aim is to analyze the production process of one of the Printed Circuit Board (PCB) production line and find out possibility of productivity and lead time improvement. Value Stream Mapping is used to check the current production flow of one product family of PCB. VSM is a lean manufacturing tool that helps to identify and remove seven deadly wastes. eVSM software is used to draw the Current State Value Stream of the production flow. This current state VSM is been analyzed to identify all value added and non-value added activities. Implementing flow using supermarket concept, TakT time and pacemaker analysis are also carried out. It is found that, by removing all non-value added activities and by including flow and supermarket and pacemaker process at each subassembly, considerable reduction in lead time is possible. Based on these finding, a future state Value Stream Mapping is been devised showing modified work flow with improved matrices like lead time, less waste etc. The changes needed to achieve the desired future state are summarized. Reducing the lead time of value streams through the implementation of lean methodologies would help the firm to increase current customer delivery challenges as well to plan for increased demand in the future. Through this thesis, an attempt is made to implement traditional lean methods to a high mix low volume production environment to prove that lean base concepts are applicable and does produce improvement in this kind of industry too. II. METHOOLOGY The research started by taking a tour of the plant and observations were made on the shop floor and the entire plant. Then discussions involving people from different departments of the company were conducted, so that further details of the current production process could be obtained and discussed. Information regarding cycle time, lead time, number of operators involved in each process, amount of inventory and work-in progress between processes were determined. Based on the information gathered, a current state map was drawn which depicts process flow, product flow, information flow and communication flow. Takt time and cycle time are also calculated. The data is then analyzed to see what areas need improvement by identifying non-value added activities that can be reduced and eliminated. Thereafter, the current state map is expanded into future state map followed by further discussions and analysis. Lean Keywords – eVSM , High mix Low volume, Lean , Printed Circuit Board, VSM I. INTRODUCTION As part of the growth plan of this electronic manufacturing company, it is looking at implementing lean in their facility so that they can accommodate more orders without increasing resources or investing in more machines. This study takes up production flow of one of the PCB product family and analyzes value added and non- value added activities using Value stream management tool. It then suggests improvement areas, especially better cycle time and inventory lead time. The assembly section is usually the highest concentration of labor in an electronics assembly plant, and therefore __________________________________________________________________________ ISSN (Online): 2347-2820, Volume -1, Issue-2, 2013 63 International Journal of Electrical, Electronics and Computer Systems, (IJEECS) _______________________________________________________________________ techniques are suggested for improvising the product flow, communication flow and information flow. Data collection In the study, data is collected through different means. The prominent method is to visit the production plant, walk through the length and breadth and observe activities. Recording of original data related to flow is done. An attempt is made to talk with the operators, QA of each section as well as the production engineers. Formal interview with engineers, operators, different department members, line manager and production manager are conducted. Studying the internal documentation and previous quality data helps to get a detailed picture as well like field observation. In particular, quantitative data on lead and cycle times as well as product specifications were collected, whereas field observations resulted in both qualitative and quantitative data (cycle time measurement). Fig 1: One Process with matrices in VSM Supplier loop, internal loop and Customer loop has to be separately drawn Based on the analysis above, different recommendations are provided to improve from the current stage. Possible results post lean implementation is highlighted. Improvements in key matrices across states are highlighted. Ways to remove different wastes are discussed in detail. How each non value added activity can be eliminated is looked into in details. Post elimination of waste and non-value added activates, the improved lead time, machine efficiency etc are shown. After implementing the changes like continuous flow and pacemaker process, improvements in key matrices are noted. A future value stream map including all the changes devised above is been drawn Product Family Selection All the products are analyzed for its different process stages for the purpose of identifying the ones going through similar process stages. Not only the process stages matters, but lead times across stages need to be comparable. After careful and time taking study and observation of about 10 to 13 production lines, DSM 3 series of products are found to be suitable for lean implementation .The reason being, all product variations goes through a set of sub processes with hardly any variations. The difference between lead times taken at each stage between each product variety is within a comparable limit as well. So combining them and brining then under one umbrella is possible, Recommendations for a future state map III. ANALYSIS Different products being manufactured at the pant are studied and their process stages re-recorded It is seen that, DSM Part Number 1080-0594-01 to 06 follow similar process stages from row material receiving till packing and shipping. It is also observed that, the difference in lead time across DSM 3 products family products are negligible compared to other products analyzed here. Create a Current State VSM using eVSM Current State Map depicts the AS-IS material and information flow of DSM 3 production. It also depicts major matrices of importance across each sub process level and a cross sub assembly levels. Supplier details and customer details are captured. eVSM software is used to draw current state VSM. eVSM is built on top of Microsoft Visio 2013. This software has templates specific with Value Stream mapping symbols. The current state material and information flow can be mapped by dragging and dropping appropriate symbols into the drawing pane and by including values for key performance parameters. After inserting the appropriate symbols, collected data as well as the correct names for each operation is included. After inserting the correct cycle times, the total cycle time for the specific VSM is calculated by adding up the individual cycle times together. Current State Processes and Statistics Production of DSM 3 consists of a chain of processes to convert the row material to finished good product. The production steps of DSM 3 product family is shown below. The process starts when row materials in cartons in packed state, are been delivered to the shop floor for SMD and delivered to the kitting area for Through Hole. Any pre- processing to be done on the components like cutting the edges etc for through hole components is to done at kitting area. Once order to make is been given to shop floor, loading/unloading team comes to the shop floor , unpacks the cartons of components and starts loading the components to the pick and place machine. Operators do setup for Screen Printing, Pick & Place __________________________________________________________________________ ISSN (Online): 2347-2820, Volume -1, Issue-2, 2013 64 International Journal of Electrical, Electronics and Computer Systems, (IJEECS) _______________________________________________________________________ and Reflow oven machines. Appropriate programs have to be loaded to all these machines. located at 1 KM distance from the plant plot. Only when kit pulling is initiated by the planning department, the boxes of row materials for that order would be retrieved from the warehouse to the kitting area. The customer sends separate boxes for SMD and Through Hole area. Supplier loop is shown in Fig 3. ICT, FCT and Packing is located in a different building, approximately 400 meters away from the production floor. Work in progress Printed Circuit Boards need to be transported to the building where testing and packing team is located. Packed PCBs in cartons, ready to be shipped would be moved to 2nd floor of the same building, from where it will be picked by shipping team by 2 PM every day. Current state value stream Current state of DSM 3 product family is drawn after considering both material and information flow between and through the production line. The value stream includes the value adding and non-value adding activities that are required to bring a product from raw material through delivery to the customer. Fig 3: Supplier Loop Customer Loop of VSM Customer has projected a monthly demand of 10000 pieces. There are slight variations across months. Monthly average delivery of finished goods to customers is 8000 to 10000 pieces. The finished goods are delivered as pallets. One pallet contains 720 units of finished good. This many printed circuit boards are usually packed in 12 boxes, where each box contains 60 pieces of finished goods. In one week customer expects 1 pallet to be delivered. The finished goods are stored in warehouses. The cartons of 60 pieces would be delivered to customer on a daily basis. Daily Target is to send 2 boxes full or cartons, so that by 6 days 12 cartons can be sent. Internal loop is given in Fig 4. Material Requirement Planning (MRP) and Master Production Schedule (MPS) runs twice monthly. Monthly sales plan will be provided by Program Management Team.6 months forecast also would be given .Inventory availability report is generated based on the sales forecast and procurement order would be generated and would be send to SCM team. SCM team creates purchase orders and sends through email to suppliers. For confirmed orders, product build option is run which will generate Dynamic shortage list. Based on this Work Order would be generated. Work order status can be ‘Released against a customer order’, or Firm planned is where plan is confirmed or planned. Planned is system generated and deleted orders. Once an order is the status changes to ‘Production Plan release ‘, a Kit loading Plan would be generated. A daily production plan gets generated which would be communicated to the production team. There is a separate plan called Machine loading to finished good plan. Management information system for reporting is also gets generated. Takt Time = Effective work time per shift / Customer requirements per shift TT = Available production time / Total daily Quantity required. Takt Time is calculated as 3 minutes. In order to achieve standard output in each shift, production crew has to produce 1 piece of PCB in 3 minutes. Customer is buying this product at a rate of one every 3 minutes. Customer loop of VSM is shown in fig.2 The analysis is based on the three lean principles: specify value, identify value stream and make value flow. The analysis starts with an understanding of how customers perceive value. Next, visualize the value stream of DSM 3 flows including the analysis of time frame and ownership in the order fulfillment process. The main focus will be on the waste identification in the flow and the solutions to reduce the influence of identified wastes. Furthermore, possible lead time reduction due to waste and bottleneck elimination will be calculated. Analysis on making the process more lean and continuous will be done. In addition, lot size analysis would also be conducted Fig 2 : Customer Loop Internal Loop of VSM Supplier Loop of VSM Entire components per order is been delivered to the warehouse by the supplier directly. The warehouse is __________________________________________________________________________ ISSN (Online): 2347-2820, Volume -1, Issue-2, 2013 65 International Journal of Electrical, Electronics and Computer Systems, (IJEECS) _______________________________________________________________________ DATE TITLE 4/14/2013 by machine (SMD), the possibilities of frequent errors are not there. So inspection based on a sampling need to be considered. So 100% inspection is not needed. Current State Value Stream FILENAME CURRENT VALUE STREAM.VSDX DESCRIPTION Current state VSM of Printed Circuit Board Production Flow REVISED 4/24/2013 A130 Supply Chain Management all Planning and Control Department Program Management Supplier Customer Ways to remove waste: Customer Item xx Demand Day Warehouse Reduce set up time: To avoid searching time and to reduce waiting time to load reels to machines, reels need to be colored or use colored label to differentiate between 100s of components. Component value checking is performed twice for all components, by loading team & by QA. QA team can check for sampling rather than 100% validation. All QA check needs to be done in parallel to loading to the machine time. Make trays of 50 PCBs already before screen printing gets finished for one batch. Weekly Production Schedule Row Materials In process Circult Testing ( ICT) Production Through hole Production SMD Functional Testing ( FCT) Final Inspection Packing Row Materials A020 1 A110 Loading 5 Machine Time 0 Min 1 2 Machine Time 40 Sec Manual Time 5 Hr Manual Time 10 Sec Process Lead 50 Sec Time StUp Setups 10 Min Day Wait 5 Min Transport 0 Min Time Utilization 1 % Utilization 1 % operators 5 1to10 operators 2 +1 1to10 shift N/A 1to10 Lot Size 50 Ite m 1 Pick and Place Process Lead 5 Hr Time StUp Setups 15 Min Day Wait 0 Min Transport 0 Min Time shift A140 Screen Printing 2 A160 1 A170 Reflow Oven 2 Machine Time 1.8 Min Machine Time 7 Min 1 A180 1 A190 1 Reflow Inspection Manual Stuffing Wave Soldering 3 5 2 2 1 3 1 1 A240 1 A250 Download 1 1 1 RF 1 A270 1 Sourcing Burning 1 1 1 A280 1 4 1 Packing 1 Machine Time 12 Min Machine Time 5 Min Machine Time 8 Min Machine Time 6 Hr Manual Time 5 Min Manual Time 2 Min Manual Time 7 Min Manual Time 5 Min Manual Time 1 Min Manual Time 1 Min Manual Time 1 Hr Manual Time 1 Min Manual Time 8 Min Manual Time 3.5 Min Process Lead 5 Min Time StUp Setups 50 Min Day Wait 0 Min Transport 1 Min Time Process Lead 5 Min Time StUp Setups 5 Min Process Lead 7 Min Time StUp Setups 5 Min Process Lead 5 Min Time StUp Setups 5 Min Process Lead 2 Min Time StUp Setups 3 Min Process Lead Process Lead Process Lead 13 Min 6 Min 9 Min Process Lead 7 Hr Time Time Time Time StUp StUp StUp StUp Setups 0 Setups 0 Setups 0 Setups 20 Min Min Min Min Process Lead 6 Min Time StUp Setups 1 Min Process Lead 8 Min Time StUp Setups 1 Min Process Lead 3.5 Min Time StUp Setups 3 Min Transport 1 Min Time Transport 3 Min Time Transport 1 Min Time Transport 2 Min Time Transport 0 Min Time Transport 0 Min Time Transport 0 Min Time Transport 2 Min Time Transport 1 Min Time Transport 1 Min Time Transport 1 Min Time Utilization 1 % Utilization 1 % Utilization 1 % Utilization o % Utilization 1 % Utilization 1 % Utilization 1 % Utilization 1 % Utilization 1 % Utilization 1 % Utilization 1 % Utilization 1 % Utilization 1 % Utilization 1 % Utilization 1 % operators 2 1to10 operators 2 1to10 operators 3 1to10 operators 5 1to10 operators 2 1to10 operators 2 1to10 operators 3 1to10 operators 1 1to10 operators 1 1to10 operators 1 1to10 operators 1 1to10 operators 1 1to10 operators 1 1to10 operators 4 1to10 operators 1 1to10 1 at a time shift 1 1to10 shift 2 1to10 shift 1 1to10 shift 3 1to10 shift 0 Min 2 1to10 Wait shift 0 Min 2 1to10 Wait shift 0 Min 2 1to10 Wait shift 0 Min 3 1to10 Manual Time 1 Min Wait shift Manual Time 1 Min 0 Min 3 1to10 Wait shift 0 Min 3 1to10 Wait shift 0 Min 3 1to10 Machine Time 5 Min A290 Final Inspection Manual Time 10 Min Wait Machine Time 1 Min 1 A260 Analog Process Lead 10 Min Time StUp Setups 5 Min Day Wait 1 Min Transport 1 Min Time 2 Min Machine Time 0 Min A230 ICT Manual Time 0 Min Wait Machine Time 0 Min A220 Final Inspection Process Lead 7 Min Time StUp Setups 30 Min Day Wait 1 Min Transport 1 Min Time 3 1to10 Machine Time 3 Min A210 Manual Time 2 Min shift Machine Time o Min 1 Post Wave Soldering Inspection Process Lead 3.8 Min Time StUp Setups 3.5 Hr Day Wait 2 Min Transport 1 Min Time 3 1to10 Machine Time 0 Min A200 Wait shift 0 Min 3 1to10 Machine Time 0 Min Wait shift 0 Min 3 1to10 Machine Time 0 Min Wait shift 0 Min 3 1to10 1 at a time No lot size 1 at a time 1 at a time 1 at a time 1 at a time Reduce Waiting Time: Reels of the same components need to be grouped and hanged on the stand by loading team. Piling up reels in cartons and making operator searching for it need to be stopped. Reel size need to be in proportion to number of components per board and order size. This helps in minimizing reel changes and thus reduces waiting time. Fig 4: Internal, Loop Sub Assembly 1 – Surface Mounting Process (SMD) Waiting time across Top and Bottom processing for a single PCB does vary from 40 to 70 % of the total order processing time per order. Statistics are given in s table1. TakT time analysis for SMD Table 1: Statistics of SMD Bot tom Top Tot al Setup Time (Per order) 1.47 hours 2.12 hours Lead Time (per board) 13.49 min 14.50 min 3.59 s 27.99 Waitin g Time (across a day) # Oper ators # Shifts 5 hours 3 Opera tors + 1 QA 3 Fig 5: Takt Time analysis for SMD Following are the wastes which has significant impact on the performance of the SMD process Bottleneck Process : Clearly Reflow inspeciton which takes 5 minutes per top and bottom is the bottleneck, whose cycle time is way above the cycle time of rest of the processes and also way abo ve th takt time. Ways need ot be identified to reduce or normalize reflow inspeciton stage to correspond to the Takt time to manage the current delivery promises to custoemr. High Waiting Time: Every stage has considerable waiting time which can be reduced. Pick & Place stage has the maximum waiting time, the main reason being component error outing and component reels getting over. Component reels get over frequently. Entire process waits for reel re-loading. Searching and loading a reel takes a lot of time. Pacemaker Process : A loop is any set of operations through which there is continuous flow. In this case, loops would indicate the manufacturing lines comprised of all of the different processes. The Pacemaker at each loop is the process which sets the pace for the entire manufacturing line. The term may be used interchangeably with the term of a bottleneck; however, they are not equal. The pacemaker is usually the most upstream process in a continuous flow loop . The concept of Takt time should be implemented to control the process. The pacemaker is mostly useful in production lines, and manufacturing cells which show fairly consistent product families. Unnecessary Motion: Operators walk across the length of the entire SMD process (~300 meters) multiple times. During reel changes, operators has to walk across to the loading table at the beginning of BAY 4, find the reel , walk back to the reel to feeder loading reels would be located at the central loading table, Over processing: Reflow inspection usually takes 5 minutes for top and 5 minutes for bottom. So a total of 10 minutes per board is taken. The defects identified at this stage are very les. Since the entire chain is handled __________________________________________________________________________ ISSN (Online): 2347-2820, Volume -1, Issue-2, 2013 66 International Journal of Electrical, Electronics and Computer Systems, (IJEECS) _______________________________________________________________________ The first process in the chain of processes in SMD , screen printing takes only 41 seconds ot finish a panel . The pick & place machie also take only less than a minute to procss a panel, bu the man time required there to place components manually delay the etnire process. Because of the man itme, the total cycle time for Pick & Place process is high near to the Takt time. If this process can perform with lesser lead time,then even reflow oven can funtion with better utilization as it can take nearly 8 to 9 boards at a time . If reflow oven taken 8 boards with a processing time of 7 minutes, then the cycle time for each board within reflow oven comes down to below 1 second. So total cycle time up to reflow inspeciton can be made less than 1 second for each of the processes , which is a huge increase from current status. Rework post reflow is too less ~ 0.25 % and hardly any rejections. So inspection needs to be made on sampling basis. Inspect all of first batch (50) of boards and then 5 boards per batch. Inspection has to be made online Waiting time Set up Time Maintenance 1.14 m 1.47 h 1 hour Top 10.24 m 3.12 m 2.12 h Maintenance 1 VA + NVA Sub Assembly 2 – Through-Hole Process Total 163 h Waiting time in Wave soldering area: This is already described above. The only way to remove this waiting time is to utilize the machine in full capacity by introducing more frames. Operators need to be make sure that 7 to 8 frames are loaded in the machine sequentially. Increase number of frames of the fixture for boards for wave soldering so that machine can be used for its maximum capacity. Currently the number of frames varies in the range of 2 to 5 for different versions of DSM. The machine has the capacity to take 10 frames at a time. As shown above, machine utilization is way less than norm. 35.5 3.59 1 Transportation: By introducing supermarkets between wave soldering and Inspection stages, transportation between stages can be reduced a lot. Table 2 Final matrices of current state Bottom 9.43 m VA + NVA Waiting Time in stuffing area: Currently operators push the board to the next person through a slider. Productivity of each operator cannot be validated through this set up. So conveyor belt can be introduced for stuffing which happens in sequential order between 5 operators. This helps to reduce the productivity issues per operator. Analysis of Value added Vs Non value added activities: For an order size of 1000 PCBs, 500 boards are processed. Each Panel that is processed has 2 PCBS in it. Bottom Lead time Total is 9.43min. Top Lead time Total is 10.24. Pick & Place machine waiting time is 40 to 70 %. Final matrices of the current state are shown in table 2. Cycle Time 3.59 Since the board has already soldered with components by the SMD process, those components need to be protected from the soldering process. for this purpose, machine inserted components need to be shielded with the use of a frame in such a way that only those newly inserted components would be exposed through the soldering process. Thus wave soldering is a combination of manual and machine process. Post soldering and cooling, the boards need ot be inspected for the newly inserted components to make sure they are placed at the correct location, and the soldering is proper etc. Post this inspection, boards need to be moved to the testing section. So a final inspection of all the boards, a through checking based on a checklist is performed to ensure quality .Any defect found are re-worked and the details are entered into the computer for logging purpose. Boards are then temporarily stored for transportation to another building. This stage comprises of following sequential steps Stuffing-- > Wave Soldering -- > Post Wave soldering Inspection Final Inspection are the sequence of operations. Bottleneck Process Analysis – Reflow Inspection: As evident from figure above, lead time for reflow inspection is way too above the allowed or desired Takt Time. So clearly this stage is a bottleneck and the first place in the value chain where work in progress inventory is piled up. Since the entire processes before reflow inspection is done by machines (as per the modified VSM), the possibility of errors would be continuous which can be easily identified though sampling than 100 % inspection. This is also proved by the following observation. Set up Time Unnecessary motion: A method need to be devised remove unnecessary motion of operators between beginning and ending of Wave soldering process to collect the fixtures. This is identified as a waste. Table 3 shows as is statistics for current state value stream. The statistics are per order processing time, final matrices, value added and non-value added activities Table 3 Final matrices of current state Cycle Time Waiting time 163 35.5 VA + NVA NVA __________________________________________________________________________ ISSN (Online): 2347-2820, Volume -1, Issue-2, 2013 67 International Journal of Electrical, Electronics and Computer Systems, (IJEECS) _______________________________________________________________________ Table 4 Final matrices of current state Cycle Time Waiting time Set up Time Maintenance /down time Bottom Top 18 min 6.5 min 20 min 6.5 min 1.08 hours 3 hours 1.08 hours components takes 2 to 3 min additional whereas same can be done by machine in no time if sufficient feeder sticks available. The entire SMD process gets paced based on this manual intervention and lead time increases. If this manual intervention can be included in the machine pick & place process, entire SMD process can be automated and pacing becomes better. Total for 500 boards 316.6h 54.16 2.16 3 Ways to make SMD process continuous: Over Processing: 100 % inspection i.e. inspection of every single board in every order, takes a lot of time. But the amounts of defects identified are considerable and rework is done immediately on the boards. Considering these facts, it is recommended. Components that are not coming is reels are currently being placed manually. It adds to the lead time. Those components need to be bought in reels itself .Getting more stick feeders is another option. Between batches of 50, the board loading is manual where boards are loaded one by one. This need to be changed to pre-loading of 50 boards and loading of the tray to the machine after each batch. Super Market pull system analysis : An inventory supermarket (kanban stock point) like a supermarket is a place where small inventory is available and one or more downstream customers come to the supermarket to pick out what they need. The upstream work center then replenishes stocks as required. When continuous flow is impractical, and the upstream process must operate in batch mode, a supermarket reduces overproduction and limits total inventory. Supermarket Pull Systems have proven to be very efficient at eliminating wastes caused by overproduction. By linking the bulk of the operations to the customer´s demand, companies have seen a lot of success. However, pull systems are very difficult to establish in a high-mix, low-volume environment. The reason for this is that a very high amount of WIP needs to be kept in order to have a stock of all of the different types of product. However, the production mix as the product goes downstream should be analyzed to see where it is not very necessary to maintain a lot of WIP. Fig 6: Takt Time analysis Bottleneck Process: As clearly seen in the graph above, lead time of each sub process across top and bottom is way too above the recommended Takt Time. The main drawback of this stage is that, it is a totally non continuous flow with each stage functions independent of other, though sequential in stages.. Wave soldering process has the highest lead time and clearly main bottleneck. Stuffing process is another candidate for improvement. Since stuffing is completely manual, there is more room for mishandling and errors as well. IV. RESULTS Pace maker Process: Because of the non – continuous flow of nature, no pacemaker process can be identified as though-hole sub assembly. Both the inspection stages are currently carried out 100 %, i.e. for each and every panel is inspected. Manual logging of details like errors identified and fixes given etc also need to be carried out. Since there are few reworks happening at each of the inspection stages, it is advisable to continue with the inspection stages. A method study needs to be done on the process to see what all sub activities can be automated Future State VSM Statistics for Sub Assembly 1 – SMD Process After the implementation of changes to SMD to remove the manual intervention, the modified statistics would be as follows. Man time would be completely removed. The additional component, with the help of stick feeder would be inserted by the machine itself. So the total lead time is reduced from 19.67 to 8.81.Since reflow oven has the capacity to take up to 10 PCB panels at a time, as the pick & place machine releases PCBS in a faster pace, reflow oven would be able to process them in the same pace. Hence the utilization of reflow oven also increases. Though it takes 7 minutes ti process one board, if 4 cards flows through the machine at any given point of time , its averaged lead time per board would be less than or equal to 2 min. Further analysis of the Current State Map Continuous flow through production line analysis: In SMD process, between pick & Place and re-flow oven, the flow becomes non continuous due to the intervention of operator s. Manual time to place ½ __________________________________________________________________________ ISSN (Online): 2347-2820, Volume -1, Issue-2, 2013 68 International Journal of Electrical, Electronics and Computer Systems, (IJEECS) _______________________________________________________________________ process, once that process is levelled out, reflow oven starts getting frequent boards and its utilization has increased proportionately. Reflow inspection, which was considered as a real bottleneck is handled with the help of sampling methodology. The latest statistics is given in figure 7. Major Future State statistics of SMD Lead time changes would be as given in Table 5 and improvement matrices for SMD is given in Table 5. Table 5 Future statistics for SMD Botto m Top Total Lead time(Curren t State) 9.43 min Setup Time(Futur e State) 4.10 min Improvemen t 43% 10.24 min 4.71 min 46% 19.67 8.81 45 % Ways to reduce set up would be the following. Introduction of color to the differentiate between reel of different components, Grouping all the reels of same components to one tag ,For getting bigger sized reels for most frequently used components in any given order. I.e. Instead of giving standard sized reels, Supplier has to be given bigger sized reels based on the order size to avoid frequent reel changes and to reduce searching required form the high number of components with repetition. Since the components are supplied by AM technologies itself, and increased demand is their own requirement, they would be more than ready to help SFO with these changes. Discussion with SCM team confirmed that, reel size can be adjusted if already mentioned to the suppliers or if guidelines can be given to them. Post these changes are implemented, the improvement matrices for SMD would be as given in Table 6. Figure 7: Pacemaker analysis Following are the recommendations to improve future state statistics for through-hole process. Stuffing: Introduction of a conveyor belt for stuffing process: Conveyor belt would increase the efficiency of working of the operators who are working in sequence to fix the components to the PCB. It would enable the workers to keep a constant pace ot the work and would not be depend on the pace of individual resources. Wave Soldering: It is a stage where 8 to 10 fixtures are introduced to the product. Operator takes 2 minutes to load a PCB into the fixture and put the frames in the conveyor of the wave soldering machine. That means every 2 minutes boards are entering wave soldering machine. Considering wave soldering machine takes 4 to 5 minutes to process a board. It would be able to process minimum 2 cards constantly in that interval. Introduce an automatic trolley system or pushing trolley system that works between the ending porting and beginning portion of Wave Soldering machine. : This would help eliminate unnecessary motion of operators between the 2 ends of the machine and the waiting time of the machine until the frames are reached at the beginning and processing has started. Table 6 Improvement in matrices for SMD Bottom Top Total Setup Time ( Per order) Current State 1.47 hours Setup Time ( Per order) Future State 40 min to 1 hour 2.12 hours 1 to 1.12 hours 3.59 hours 1.6 to 2.12 hours Changes 40 min – 54.64% 1 hour – 31.97 1 hour – 52.835 1.4 hour – 33.96 Future State - Sub Assembly 2 – Through Hole Process Improvement 31 % to 55 % 34 % To 53 % Better scheduling of stuffing and wave soldering so as to avoid the delay caused by different shift timings between the 2 operations : Currently stuffing team only works on day shift – i.e. 8 am to 4 pm – shift, where as both the previous process ie SMD and wave soldering is / can be run on all the 3 shifts . Unless cards are made available for wave soldering post stuffing, it cannot start the processing. Consider a scenario where SMD has started on second shift i.e. 4 pm 12 pm. By the time day shift starts, cards would be ready for stuffing team. During this entire processing wave soldering machine is waiting. Once manual stuffing starts processing, cards gets piled up as wave soldering machine is slow 30% To 55 % Final result of Pacemaker and Flow changes of SMD Pick & Place process was identified as the pacemaker process. By removing manual intervention, lead time is reduced as well continuous flow is ensured. This resulted in considerable lead time reduction in that process stage alone. Since pick & place is a pacemaker __________________________________________________________________________ ISSN (Online): 2347-2820, Volume -1, Issue-2, 2013 69 International Journal of Electrical, Electronics and Computer Systems, (IJEECS) _______________________________________________________________________ compared to the manual stuffing. Better sequencing between the 3 operations is necessary. process, once that process is levelled out, reflow oven starts getting frequent boards and its utilization has increased proportionately. Future State Lead Time Reflow inspection, which was considered as a real bottleneck is handled with the help of sampling methodology described in last chapter. The latest statistics would be as given in figure 8. Lead time changes are shown in Table 7. Set up time is 150 minutes per board, which cannot be reduced more than this. Stuffing needs maximum 50 minutes to load all components. Table 7 Lead time improvements for Through-hole Lead Lead time Time Improvement (Current (Future State) State) Bottom 18 min 14 min 22% Top 20 min 16 min 20% Total 38 30 21% Machine Utilization & Waiting Time Results The 2 proposals to decrease waiting time as well increase the utilization of Wave soldering machine considerably are . Figure 8: Future state Takt Time analysis & Result V. CONCLUSION 1. Increase in number of frames per product versions of DSM: Number of frames increased to 10 per product version from current number of 2 / 4 would considerably reduce waiting time for the machine. Once the machine starts processing more frames within the stipulated 4 minutes timeframe, the average processing time per frame would reduce to as less than 1 minute. If lead time can be reduced with the introduction of lean tools and methodologies more PCBs can be produced with the available machine and resources. Value Stream mapping tool of Lean is used in this plant to analyze current production processes in detail for a selected product family DSM. DSM has 6 versions of products being produced almost throughout the month, with a current requirement of 8000 to 10000 pieces per month. 2. Enable automatic or mechanical movement of frames back to the beginning of the chain than the current operator lead movement.The time taken to move the frames back to beginning of the machine workstation after cooling and removal of board from the frames adds to the waiting time. It also adds fatigue to the operator to move between the work stations in frequent duration just to pass the empty frames. By identifying waste at SMD, through- hole, testing, final inspection & packing sub-assemblies, lead time reduction is made possible. Also by introducing flow and pacemaker processing through TakT time analysis, lead times have been levelled across stations. Considerable improvement in lead time is made possible across all the three sub-assemblies of DMS production. Machine utilization has increased. Producing to Takt time is been made possible across the value chain. This modified statistics shows that, it is possible to meet the increased demand of the customer with the available resources; facilities provided all the suggested changes are implemented. With increased number of frames, lot size is also increased from 2 or 4 to 8 or 10. So the processing time has reduced to the new processing time + cooling time. Waiting time improvement is found to be 66 % as given in table 8. Table 8: Waiting time improvements for Through-hole Current State 50 hours Future State 16.6 hours Thus Value Stream Mapping is proved to a very valuable tool for analysis of Current value stream of a high mix low volume production scenario. Identifying waste and removing it, implementing flow concept and Takt time levelling are powerful concepts which are able to bring phenomenal improvements to current state of production flow. Waiting time reduced to 66% Final result of Pacemaker and Flow changes Pick & Place process was identified as the pacemaker process. By removing manual intervention, lead time is reduced as well continuous flow is ensured. This resulted in considerable lead time reduction in that process stage alone. Since pick & place is a pacemaker Owing to lack of time, all changes proposed could no be implemented to observe results and hence possible output only could be included in this thesis. As an __________________________________________________________________________ ISSN (Online): 2347-2820, Volume -1, Issue-2, 2013 70 International Journal of Electrical, Electronics and Computer Systems, (IJEECS) _______________________________________________________________________ extension of this work, the results can be verified through simulation. reduction: an Indian case study. Production Planning & Control, 2005 REFERENCES [4] Hines, P., Rich, N., Bicheno, J., Brunt, D., Taylor, D., Butterworth, C. & Sullivan, J.. Value stream management. International Journal of Logistics Management, 1998 [5] Tapping , D.,Luyster, T., & Shuker, . T. Value stream management: Eight steps to planning, mapping and sustaining lean improvements. NewYork , NY : Productivity Press, 2002. [1] Peter Hines, Nick Rich, The seven value stream mapping tools, Lean Enterprise Research Centre, Cardiff Business School, Cardiff, UK. [2] The basics of Value Stream Mapping, , CMTC California Manufacturing Technology Consulting, San Fernando Valley Secti, 2003 [3] Seth, D. & Gupta, Application of value stream mapping for lean operations and cycle time __________________________________________________________________________ ISSN (Online): 2347-2820, Volume -1, Issue-2, 2013 71