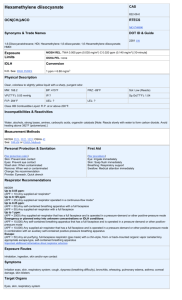

assigned protection factor table

advertisement

Respiratory Protection in Workplace A. H. Mehrparvar, MD Occupational Medicine department Yazd University of Medical Sciences Airborne contaminants Particulate (aerosol) Dust Mist Smoke Gas Vapor Methods of controlling airborne contaminants Engineering controls (elimination of the hazard) substitution Isolation vetilation Administrative controls Personal protective devices Respiratory personal protective devices (respirators) used to protect against inhaled agents or to improve the quality of inhaled air An effective component of a worker protection program Used for protection against chemical agents (e.g., asbestos, lead), and biologic agents Use of Respirators not the method of choice for controlling exposures completely dependent on voluntary compliance by the worker requires an ongoing multifaceted program to ensure proper maintenance and utilization When respirators are needed? when the work is of a varied nature, preventing the construction of adequate engineering controls during maintenance and repair operations when ventilation controls are disengaged or nonoperative. when relatively infrequent operations are conducted (e.g., transfers of liquid raw materials). for emergency and unplanned events (e.g., as part of the emergency response to a spill) or when the agent is unknown. when product substitutions or engineering controls are not financially feasible. Different kinds of respirators (a) air-purifying respirators use ambient air and filter or adsorb the contaminants (b) atmosphere-supplying Most respirators in use are air-purifying respirators. Generally, atmosphere-supplying respirators provide a higher level of protection. Air-purifying respirators decrease contaminant levels by several mechanisms: Filtration Electrostatic characteristics Sorbent respirators Air- purifying respirators Mechanical filter Chemical-cartridge respirator Gas mask Powered air-purifying respirator Mechanical-filter respirator For particulates 3 kinds: N (Not resistant to oil) R (Resistant to oil) P (oil Proof) efficacy 95 99 100 Chemical-cartridge respirator For vapors and gases Cartridge contains chemical to absorb gases and vapors Gas mask Designed for: Organic vapors and gases Alkaline gases Acid gases Pesticides Paint vapors Radioactive particulates Dusts Fumes Mists Full face Use a canister (sorbent: 2-10 times a cartridge) Powered air-purifying respirator (PAPR) Used for particulates, gases and vapors Atmosphere -supplying Self-contained breathing apparatus (SCBA) Air line: air via a hose Combined air line with backup tank SCBA Airline Combination Atmosphere -supplying Continuous flow Demand: air flow only during inspiration Pressure demand: attempts to maintain mask pressure positive throughout respiration Mask type Quarter mask Half mask Full-face mask Other (e.g., air hat) Quarter Mask Half Mask Full Face Fit type Tight fitting Loose fitting Tight-fitting respirator Loose fitting- PAPR helmet Respirator efficacy The overall efficacy of the respirator is described by protection factor. Protection factor: the ratio of the contaminant concentration outside the mask to the concentration inside the mask. Assigned protection factor (APF) Measured protection factor (MPF) Workplace protection factor (WPF) Usually MPF>APF>WPF Fit Testing and Checking Every time a user dons a respirator, should perform a fit check Typically for the first time Qualitative and quantitative fit tests Qualitative: detection of a tracer material by the subject. Quantitative: concentration of a marker substance inside and outside the mask is measured under laboratory conditions for the specific user. Occupational Respiratory Protection Program Assessment of whether respirators are needed Exposure assessment Respirator selection Medical assessment of users Training Cleaning and maintenance Program audit Respirator Selection Two factors inform respirator selection: exposure situation per se worker medical condition Worker preferences Sequence of activities Should respirators be used at all? What are the exposures of concern? What degree of contaminant reduction is necessary? permissible exposure level (PEL). The ratio of the actual workplace exposure level to the permissible exposure defines the degree of reduction that the respirator must afford. the 8-hour time-weighted average (TWA) short-term exposure limits (STEL) What safety factor is necessary? A safety factor of tenfold is added Greater safety factors are needed with highly toxic agents on unpredictable exposures. single-use disposable respirators have a maximum assigned protection factor of 10 ppm The fit test may misestimate the actual workplace protection by a factor of ten. Meaningful fit testing for single-use respirators may not feasible since their protection factor is only ten at most. Is there an immediately dangerous to life and health (IDLH) situation ? Does the agent have good warning properties ? an atmosphere-supplying rather than an air-purifying respirator is generally required. In particularly hazardous situations, dual protection is necessary to ensure safety a full-face mask with positive pressure mode operation is employed to avoid inward movement of contaminants during inspiration. End-of-service-life indicators (if available) are necessary if airpurifying respirators are employed with agents with poor warning properties. What respirator types are compatible with the work situation ? Air-line respirators cannot be used where considerable mobility is necessary. Can the individual worker safely and effectively use the respirator? Will the worker actually use the device when needed? What can be afforded? How do respirators integrate with other protective measures (e.g., protective suits)? Respirator programs must be periodically evaluated and adjusted to be effective in real-life situations. ratio of workplace air concentration to the occupational exposure level (e.g., PEL) defines the minimum degree of protection to be afforded, and greater respiratory protection may be needed occasionally. physical state of an inhaled agent Particle size greater degree of respiratory protection for small-size particles (e.g., fumes) For fibers, the dimensions and charge affect uptake and clearance Greater degrees of respiratory protection for longer duration of exposure The level of exertion Personal susceptibility Medical evaluation for respirator use Prior to respirator use Periodically during use Upon change in health status When respirator use problems are suspected A questionnaire about respiratory and other health conditions, prior to use of respirators Medical examination In some circumstances, a limited exercise test In marginal cases, observation of the worker using the respirator in the workplace or during work simulation may be needed. Periodic evaluation of users is also advisable. For special examinations of selected individuals who have expressed difficulty with respirator use, more intensive assessment of the user is warranted. Negative pressure respirators Half-face cartridge respirator Full-face cartridge respirator N95 Particulate respirator Filters and cartridges What are the ten parts of a respirator program? 1. Administrator of the Program 2. Medical Evaluation 3. Selection of Respiratory Protection Choose the right respirator to protect from contaminant-consult with EH&S. Respirators must be NIOSH approved. Evaluate workplace exposure, assume IDLH if contaminant is not known. Air purifying respirators cannot be used in IDLH atmospheres. 4. Training Initial training required with periodic refresher training every year. The training shall encompass the following: Why the respirator is necessary and how improper fit, usage, or maintenance can compromise the protective effect of the respirator; What the limitations are Use of respirator effectively in emergencies, including situations in which the respirator malfunctions; How to inspect, put on and remove, use, check the seals of the respirator Maintenance and storage procedures How to recognize medical signs and symptoms that may limit or prevent the effective use of respirators 5. Fit testing for all tight fitting respirators annually, or if changes occur to facial features, weight gain/loss, eyewear changes, fitcheck fails 6. Inspection & care inspect before each use replace defective parts immediately 7. Cleaning after each use, disassemble and thoroughly clean and disinfect respirator 8. Use inspect before using, proper storage, positive/negative fit check before each use, 9. Review Periodic audits of the UR Respiratory Protection Program 10. Record Keeping Medical certifications Training records Fit test records Air monitoring records Types of Fit Tests • Qualitative: • • Test agent directed around the head of the respirator wearer If user can detect agent, test is failed • Quantitative: • • Test atmosphere Quantifies respirator fit using instrumentation to determine the amount of leakage into the respirator facepiece Qualitative Fit Test • • • • Banana oil Irritant smoke Saccharin challenge Bitrex solution Quantitative Fit Test • • Expensive machinery Fit Factors Outside to inside concentration Standard prohibits facial hair which interferes with face - to - facepiece seal or valve function ASSIGNED PROTECTION FACTOR TABLE Air-Purifying Respirators Quarter Mask APF=5 Filtering Facepiece APF=10 Elastomeric Half Mask APF=10 Full-Face Respirator APF=50 ASSIGNED PROTECTION FACTOR TABLE Powered Air-Purifying Respirators Half Mask APF=50 Full-Face APF=1,000 Hood/Helmet APF=25/1,0004 4Must Loose-fitting Facepiece APF=25 be proven to provide APF of 1,000 or be treated as Loose-fitting Facepiece PAPR with APF=25. ASSIGNED PROTECTION FACTOR TABLE Demand Supplied-Air Respirators Half Mask APF=10 Full Face APF=50 ASSIGNED PROTECTION FACTOR TABLE Pressure Demand Supplied-Air Respirators Half Mask APF=50 Full Face APF=1,000 ASSIGNED PROTECTION FACTOR TABLE Continuous Flow Supplied-Air Respirators Half Mask APF=50 Full Face APF=1,000 Hood/Helmet APF=25/1,0004 4Must Loose-fitting Facepiece APF=25 be proven to provide APF of 1,000 or be treated as Loose-fitting Facepiece SAR with APF=25. ASSIGNED PROTECTION FACTOR TABLE Demand Self Contained Breathing Apparatus Half Mask APF=10 Full Face APF=50 Helmet/Hood APF=50 ASSIGNED PROTECTION FACTOR TABLE Hooded Demand Self Contained Breathing Apparatus The demand unit is Draeger’s Air Boss Guardian, which consists of a hood with an inner nose cup with 30 minute air supply. Neck seal forms gas-tight seal. Per NIOSH, fit testing requirements apply. Fit Test adapter, P/n 4056314 for fit testing with PortacountTM Plus ASSIGNED PROTECTION FACTOR TABLE Pressure Demand Self Contained Breathing Apparatus Full Face APF=10,000 Includes closed circuit SCBA Helmet/Hood APF=10,000 Not NFPA compliant ASSIGNED PROTECTION FACTOR TABLE Pressure Demand Self Contained Breathing Apparatus NIOSH certified the tight-fitting hooded Survivair Puma respirator as a pressure-demand SCBA with 30, 45, or 60 min air supply. Has a nosecup. Inappropriate Marketing NIOSH warns that facial hair cannot interfere with neck or nosecup seal. Fit test adapter for qualitatively fit testing Puma Combination Respirators Not in APF Table Preamble states: “…the combination pressuredemand full facepiece SAR with auxiliary SCBA respirator is equivalent to an SCBA, and, therefore, the APF for an SCBA applies. When using a combination respirator ensure that the APF is appropriate to the mode of operation in which the respirator is being used [paragraph (d)(3)(i)(A)]. Full Face PD Airline APF = 1,000 Full Face Air-purifying APF = 50